Chamber furnaces

The chamber furnaces are suitable for Annealing, Hardening and Brazing. The furnaces can be extended with a variety of accessories, like annealing boxes for operation under protective gas, roller guides, or a cooling station with a quench tank. Even high-performance applications like the annealing of titanium can be implemented without the use of expensive and complicated annealing systems.Robust insulation with light refractory bricksDeep furnace chamber with three-sides heating: from both side walls and bottomLow energy consumption due to multi-layer insulationBase frame includedN 7/H - N 17/HR designed as table-top modelParallel guided downward swinging door (user protected from heat radiation)NTLog Basic for Nabertherm controller: recording of process data with USB-flash driveEquipped with the B 500 programmable controller (with touch panel, 5 programmes with 4 segments each), optionally available with the C 540 controller

Charging rack for ashing furnaces

Charging rack to load the furnace in different levels, including holders to insert and remove the trays.

Chemical membrane pump VP1

The VP1 vacuum pump, together with the VD series vacuum drying ovens, is ideally suited for drying aqueous and non-flammable solvents.Resistant to a wide range of chemicalsVery quiet and low-vibration operationDesigned for S1 operating mode (continuous operation)Suction and pressure-side separators for collecting condensate

Chemical membrane pump VP2

The VP2 vacuum pump, together with the VD series vacuum drying ovens, is ideally suited for drying aqueous and non-flammable solvents.Resistant to a wide range of chemicalsVery quiet and low-vibration operationDesigned for S1 operating mode (continuous operation)Suction and pressure-side separators for collecting condensate

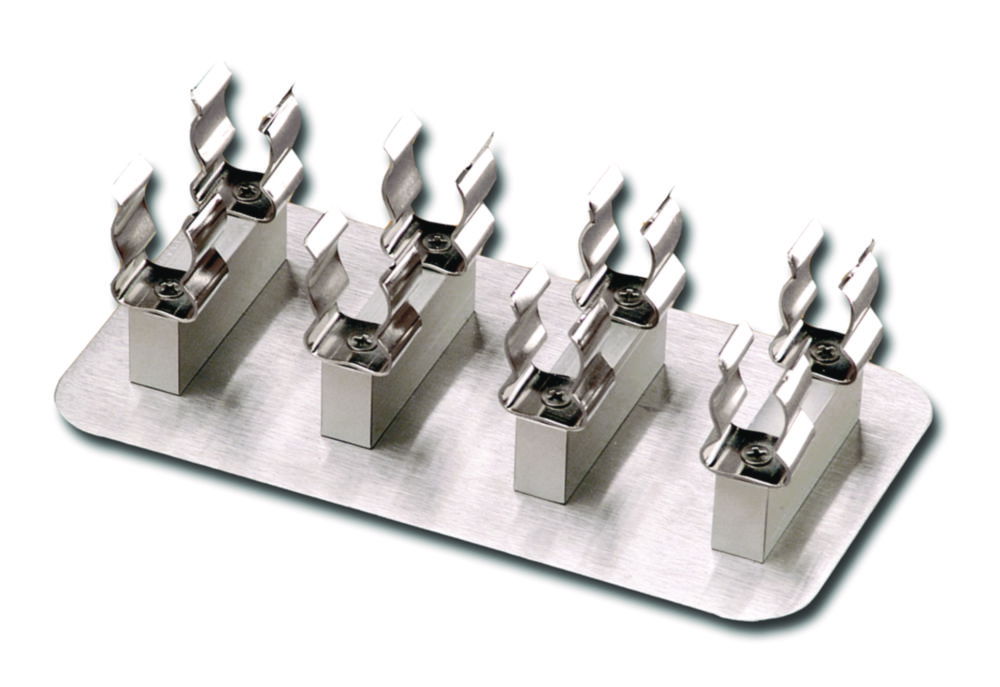

Clamps for Erlenmeyer flasks for Shaking water baths Hydro

Clamps to be placed on the shaking tray.

Climate Chambers ICH C, with humidity and CO2 control

The climate chamber generation with the unique ControlCOCKPIT for a quick and intuitive operation. Unparalleled temperature and humidity homogeneity for long-term stable ambient conditions.PID microprocessor control with integrated auto-diagnostic systemInterior stainless steel 1.4301 (ASTM 304), deep-drawnStructured stainless steel housing, rear of zinc-plated steelHigh-Operation and adjustment of all parameters directly at the ControlCOCKPIT temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standardsInternal data logger with a storage capacity of at least 10 yearsGerman, English, French, Spanish language settings available on the ControlCOCKPITDigital backwards counter with target time setting adjustable between 1 minute and 99 daysThe SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamberAdjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT, for example relative humidityMoisture tight standard entry port, at the back, 40 mm inner diameter, can be closed by silicone stopperTwinDISPLAY: ControlCOCKPIT with two TFT colour displaysAvailable parameters on the ControlCOCKPIT: Temperature (Celsius or Fahrenheit), programme time, relative humidity, time zones, summertime/wintertimeTwo Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an errorAtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB portControlCOCKPIT with USB port for uploading programmes, reading out protocol logs, activating the User-ID functionDisplaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading programmes and for online loggingMultiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.3 or 2 and mechanical temperature limiter TB (protection class 1) acc. to DIN 12880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN/MAX values for over/undertemperature alarmThe climate chamber generation with the unique ControlCOCKPIT for a quick and intuitive operation. Unparalleled temperature and humidity homogeneity for long-term stable ambient conditions.PID microprocessor control with integrated auto-diagnostic systemInterior stainless steel 1.4301 (ASTM 304), deep-drawnStructured stainless steel housing, rear of zinc-plated steelHigh-Operation and adjustment of all parameters directly at the ControlCOCKPIT temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standardsInternal data logger with a storage capacity of at least 10 yearsGerman, English, French, Spanish language settings available on the ControlCOCKPITDigital backwards counter with target time setting adjustable between 1 minute and 99 daysThe SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamberAdjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT, for example relative humidityMoisture tight standard entry port, at the back, 40 mm inner diameter, can be closed by silicone stopperTwinDISPLAY: ControlCOCKPIT with two TFT colour displaysAvailable parameters on the ControlCOCKPIT: Temperature (Celsius or Fahrenheit), programme time, relative humidity, time zones, summertime/wintertimeTwo Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an errorAtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB portControlCOCKPIT with USB port for uploading programmes, reading out protocol logs, activating the User-ID functionDisplaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading programmes and for online loggingMultiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.3 or 2 and mechanical temperature limiter TB (protection class 1) acc. to DIN 12880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN/MAX values for over/undertemperature alarm

Climate Chambers ICH L, with humidity control and light

The climate chamber generation with the unique ControlCOCKPIT for a quick and intuitive operation. Unparalleled temperature and humidity homogeneity for long-term stable ambient conditions.PID microprocessor control with integrated auto-diagnostic systemInterior stainless steel 1.4301 (ASTM 304), deep-drawnStructured stainless steel housing, rear of zinc-plated steelHigh-Operation and adjustment of all parameters directly at the ControlCOCKPIT temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standardsInternal data logger with a storage capacity of at least 10 yearsGerman, English, French, Spanish language settings available on the ControlCOCKPITDigital backwards counter with target time setting adjustable between 1 minute and 99 daysThe SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamberAdjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT, for example relative humidityMoisture tight standard entry port, at the back, 40 mm inner diameter, can be closed by silicone stopperTwinDISPLAY: ControlCOCKPIT with two TFT colour displaysAvailable parameters on the ControlCOCKPIT: Temperature (Celsius or Fahrenheit), programme time, relative humidity, time zones, summertime/wintertimeTwo Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an errorAtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB portControlCOCKPIT with USB port for uploading programmes, reading out protocol logs, activating the User-ID functionDisplaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading programmes and for online loggingMultiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.3 or 2 and mechanical temperature limiter TB (protection class 1) acc. to DIN 12880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN/MAX values for over/undertemperature alarmSpecially designed for testing pharmaceutical products according to ICH, Q1A and Q1B, option 2, and similar global standards for stability tests of cosmetics and food.

Climate Chambers ICH, with humidity control

The climate chamber generation with the unique ControlCOCKPIT for a quick and intuitive operation. Unparalleled temperature and humidity homogeneity for long-term stable ambient conditions.PID microprocessor control with integrated auto-diagnostic systemInterior stainless steel 1.4301 (ASTM 304), deep-drawnStructured stainless steel housing, rear of zinc-plated steelHigh-Operation and adjustment of all parameters directly at the ControlCOCKPIT temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standardsInternal data logger with a storage capacity of at least 10 yearsGerman, English, French, Spanish language settings available on the ControlCOCKPITDigital backwards counter with target time setting adjustable between 1 minute and 99 daysThe SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamberAdjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT, for example relative humidityMoisture tight standard entry port, at the back, 40 mm inner diameter, can be closed by silicone stopperTwinDISPLAY: ControlCOCKPIT with two TFT colour displaysAvailable parameters on the ControlCOCKPIT: Temperature (Celsius or Fahrenheit), programme time, relative humidity, time zones, summertime/wintertimeTwo Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an errorAtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB portControlCOCKPIT with USB port for uploading programmes, reading out protocol logs, activating the User-ID functionDisplaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading programmes and for online loggingMultiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.3 or 2 and mechanical temperature limiter TB (protection class 1) acc. to DIN 12880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN/MAX values for over/undertemperature alarmThe climate chamber generation with the unique ControlCOCKPIT for a quick and intuitive operation. Unparalleled temperature and humidity homogeneity for long-term stable ambient conditions.PID microprocessor control with integrated auto-diagnostic systemInterior stainless steel 1.4301 (ASTM 304), deep-drawnStructured stainless steel housing, rear of zinc-plated steelHigh-Operation and adjustment of all parameters directly at the ControlCOCKPIT temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standardsInternal data logger with a storage capacity of at least 10 yearsGerman, English, French, Spanish language settings available on the ControlCOCKPITDigital backwards counter with target time setting adjustable between 1 minute and 99 daysThe SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamberAdjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT, for example relative humidityMoisture tight standard entry port, at the back, 40 mm inner diameter, can be closed by silicone stopperTwinDISPLAY: ControlCOCKPIT with two TFT colour displaysAvailable parameters on the ControlCOCKPIT: Temperature (Celsius or Fahrenheit), programme time, relative humidity, time zones, summertime/wintertimeTwo Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an errorAtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB portControlCOCKPIT with USB port for uploading programmes, reading out protocol logs, activating the User-ID functionDisplaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading programmes and for online loggingMultiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.3 or 2 and mechanical temperature limiter TB (protection class 1) acc. to DIN 12880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN/MAX values for over/undertemperature alarm

Climatic Test Chamber CTC256

Simulate the perfect atmosphere for climate and temperature tests, specifically in accordance with DIN EN 60068-2-1, 2-2 and 2-3. Provide unlimited flexibility for controlled material and function tests as well as ageing tests.Ventilation and Control: high-performance air fan in working chamberdepending on operation status automatically variable fan speed with manual adjustment from 10 % to 100 %adaptive, fuzzy-supported multifunctional digital microprocessor PID-controllerautodiagnostic system with fault indication on temperature and humidity control2 x Class A, 4-wire circuit, Pt100 sensors, mutually monitoring and maintaining performance at the same temperature valuedigital 7-day-programme-timer with real time clock, precise minute settingintegral timer for heating profiles of up to 40 ramps, each segment adjustable from 1 min. up to 999 hoursdigital display (LED) of all set parameters, such as temperature, weekdays, time, humidity and set-up values - language to be chosen in setupdigital display of set values (resolution: 0.1 °C below 99.9 °C, 0.5 °C above 100 °C) and actual values (resolution: 0.1 °C) of temperature (LED)long-term documenting (ring store) of all relevant data, GLP-conforming as data logger - 1024 kBprogramme stored on power failureparallel printer interface (incl. real-time clock with date function) for all PCL3-compatible ink-jet printers for GLP-conforming documentationUSB interface including Memmert "Celsius" software for programming and documentationchip card control incl. one MEMoryCard XL with 32 kB (up to 40 ramps)incl. works calibration certificate for -20 °C and 160 °CHeating concept: high-performance ring heaters with optimised air circulationdoor heating to avoid condensateCooling Concept:twin compressorspeed adjustable condenser fanrefrigerant R449AMultiple Overtemperature Protection:with audible and visual alarm in case of over-/undertemperature and over-/under-humidity, open door and empty water tankindependently working, digitally adjustable electronic overtemperature controller, TWW protection class 3.3additional adjustable Auto-Safety-Function "ASF" for over- and undertemperature automatically following the set value at a preset tolerance rangemechanical temperature limiter TB class 1 switching the heating off at approx.10 °C above max. oven temperatureStandards for CTC additionally:Electronically controlled active humidification and dehumidification from 10 % to 98 % rh with digital display of the relative humidity, display resolution 0.5 %, setting accuracy 1 %incl. works calibration certificate for 30 °C at 60 % rhHumidity supply with distilled water from 2 x 10 l tanks on integrated telescopic slide, with automatic water tank change-over2 x 10 l tanks acting as condensate collectors, on telescopic slide mounts

Clip plate for volumetric flasks

Clip plate made of metal for holding volumetric flasks. The clip plate can be attached to the magnetic platform.

Clip plates for tubes

Clip plates made of metal for holding different tubes. The clip plates can be attached to the magnetic platform.

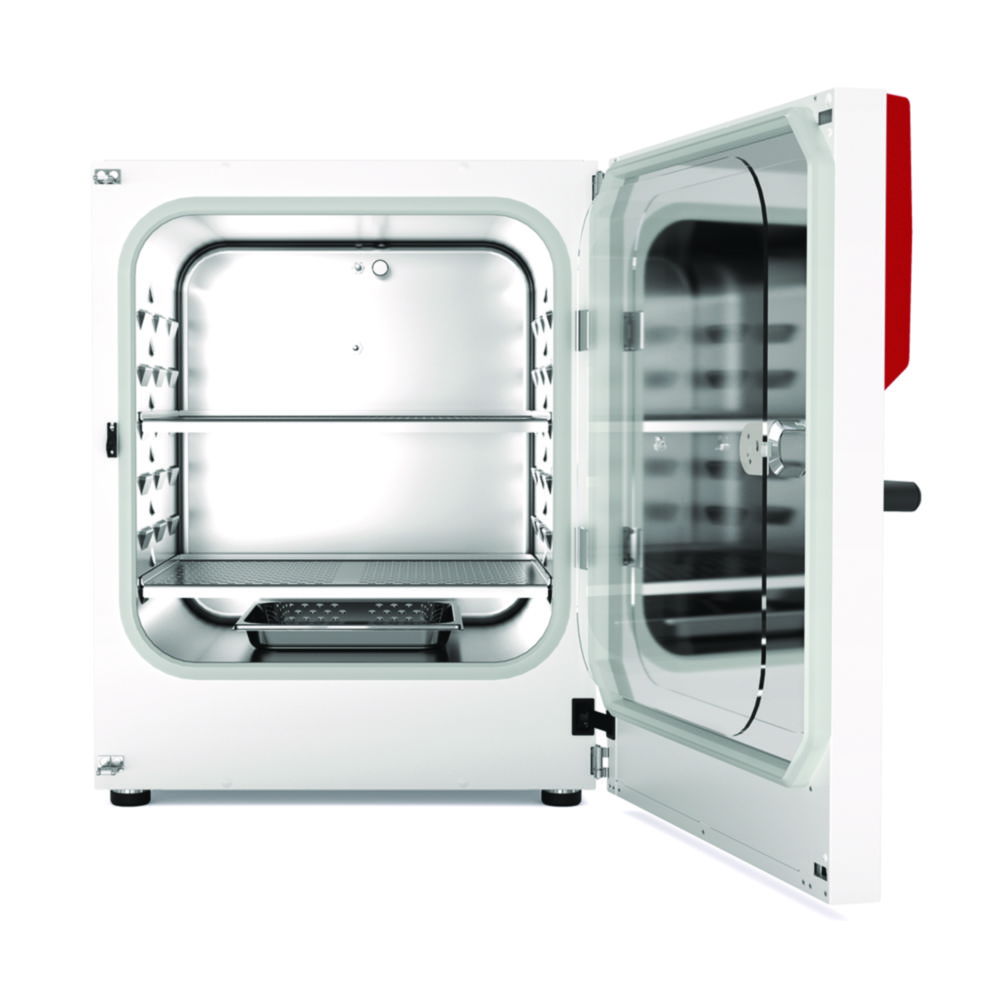

CO2 incubator ICO

The CO2 incubator is ideal for biosynthesis as well as the cultivation of cells, bacteria, and tissues in the laboratory. Thanks to turbulence-free chamber ventilation, a consistently homogeneous atmosphere is ensured.User-friendly, intuitive operating conceptControlCOCKPIT: TwinDISPLAY with 2 high-definition TFT colour displaysUSB and Ethernet interfaceSterilisation of the interior including all installations and sensors at 180 °C in 60 minutesMultifunctional all-round heating with additional door and rear wall heatingFail-safe FDA-compliant data loggingVisual and acoustic alarm as well as alarm notification when individually adjustable corridors are exceededRounded corners enable easy and thorough cleaning of the interior

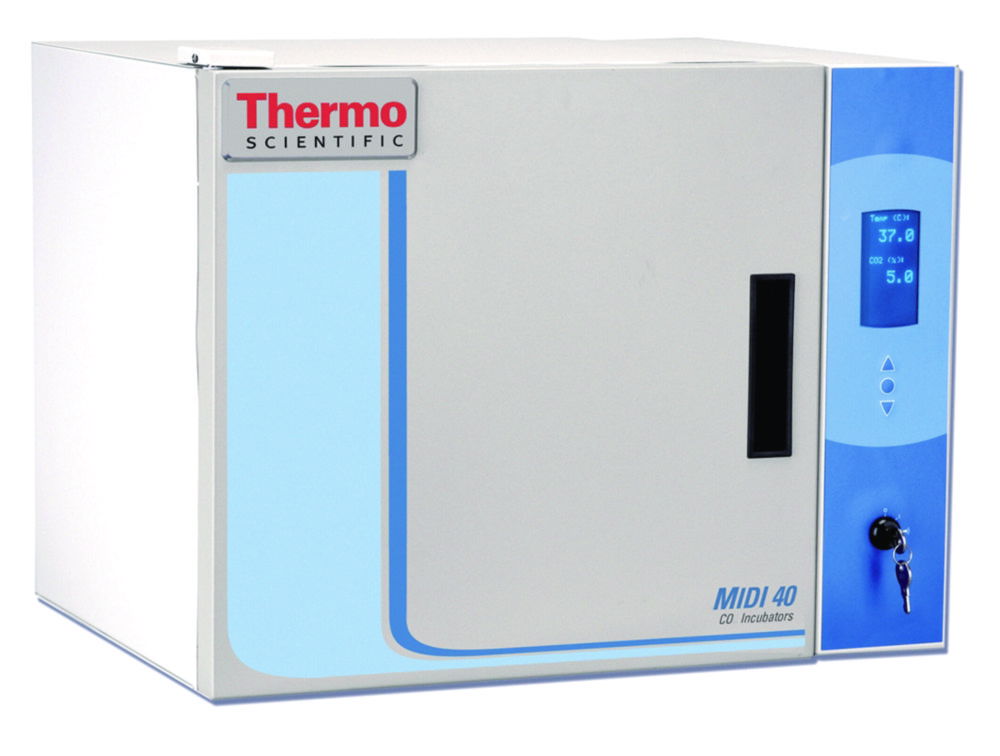

CO2 Incubator Midi 40 with small volume

The Thermo Scientific Midi 40 CO2 incubator is designed specifically for cell culture scientists who require a compact culturing workspace to handle small workloads, perform personal use applications, or simply address limited space environments. With its 1.4 cu ft (40 l) capacity, the Midi 40 adds a new dimension to the Thermo Scientific portfolio of leading CO2 incubation solutions. It delivers the performance and capabilities of full-sized incubators in a space-saving footprint, ideal for those who wish to avoid shared-use environments that can present potential contamination risk through unnecessary sample handling and repeated door openings. Easy to operate and economical to own, the fully featured Midi 40 offers remarkable value in a small footprint.Advanced IntrLogic™ II microprocessor: bright digital display and intuitive touchpad for simplified entry of temperature, CO2 and alarm data, with keyed setpoint switch to prevent unauthorised changes to your operating parameters.Stainless steel culture chamber: seamless, non-corrosive and exceptionally easy to clean. The Midi 40 is provided with four removable shelves.Highly efficient direct heating design: provides even heat distribution to all sides of the chamber, for accurate control with uniformity of +/- 0.1 °C.Precise and reliable CO2 control: featuring accurate thermal conductivity sensor located directly in the chamber, ensuring responsive control and long service life.Removable water reservoir: generates relative humidity values up to 95 % with rapid recovery rates that promote optimal cell growth.Heated inner glass door: provides sample security while preventing unwanted condensation.Convenient data communication: RS-485 signal output is standard, in addition to audible and visual alarm functions to ensure proper operations.

CO2 incubator, BBD 6220

BBD 6220 provides stable growth conditions and a high degree of security and protection against contamination. Typical applications are for IVF or pathogenic work. Range: ambient + 5 °C to 50 °C, humidity greater than 95 % R.H. and CO2 concentrations between 0 and 20 % Vol are reliably achieved via a microprocessor controlled measuring and control system. An automatic disinfection routine at 180 °C, which safely eliminates bacteria, fungi and spores, decontaminates the entire interior space including the sensors and fittings. The humidity water reservoir is located outside the chamber. The water is sterilised before it is used for humidification. The stainless steel chamber is crevice-free with rounded corners for easy cleaning. Includes "Heraeus CO2 Autozero System" overtemperature protection with separate probe and RS232 interface.

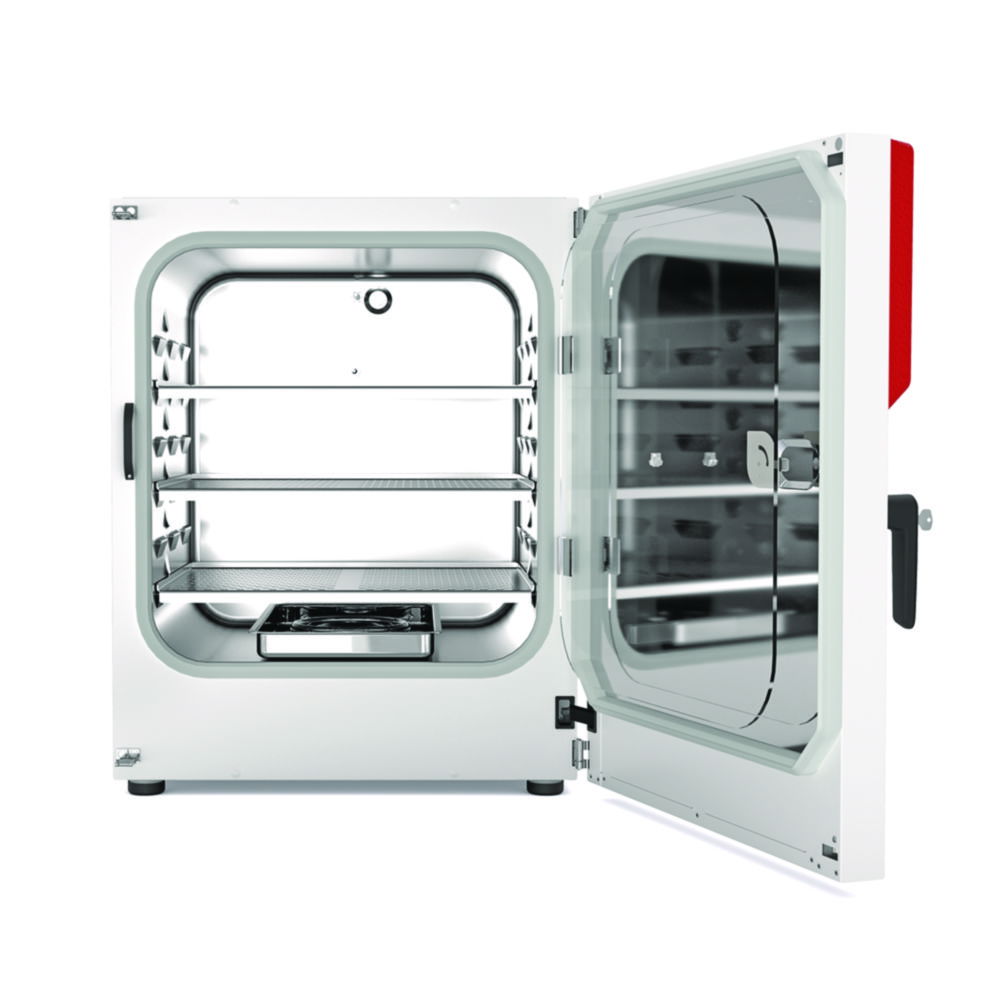

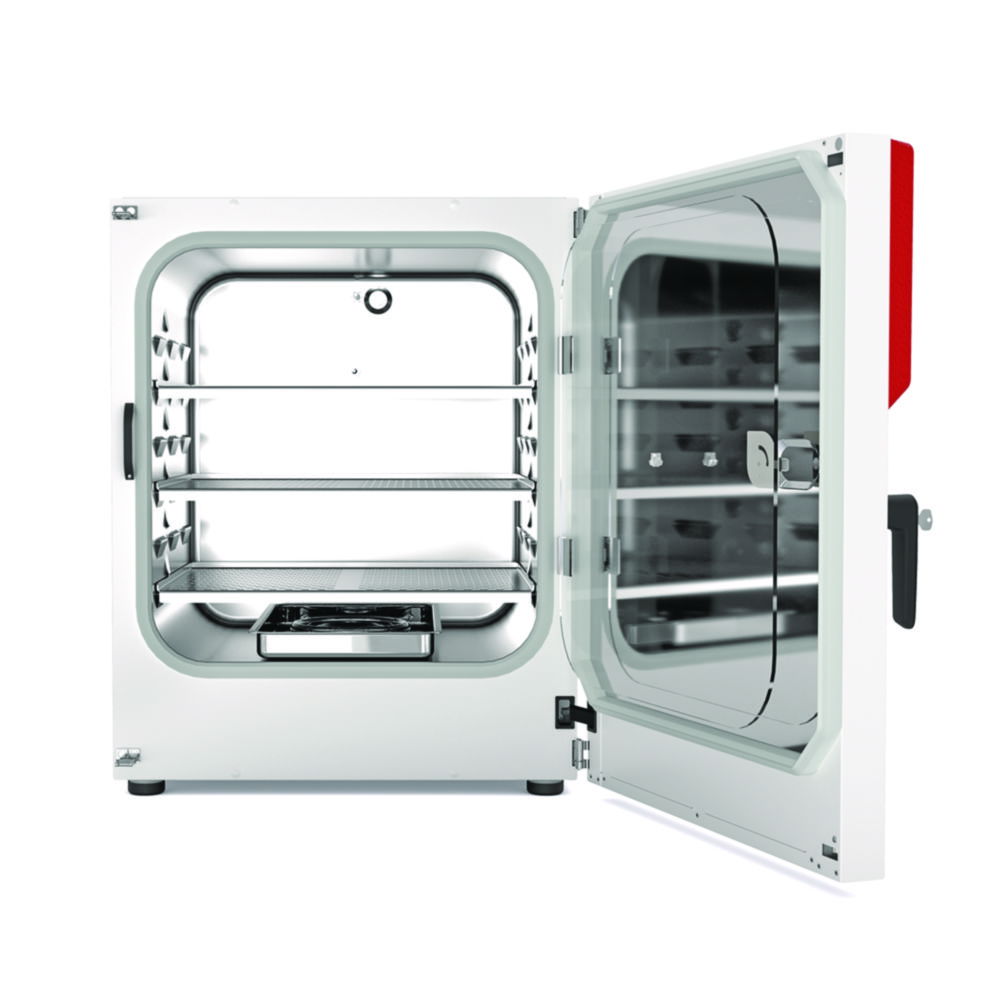

CO2 incubators CB

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactHumidification system with condensation protectionTouchscreen controllerFail-safe CO2 system for protecting the pH of cell cultures

CO2 incubators CB-O, with O2 control

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactHumidification system with condensation protectionTouchscreen controllerFail-safe CO2 system for protecting the pH of cell cultures

CO2 incubators CB-S

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactHumidification system with condensation protectionPID controller with LCD display

CO2 incubators CBF, with humidity control

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactContamination-safe humidification system without water panTouchscreen controllerFail-safe CO2 system for protecting the pH of cell cultures

CO2 incubators CBF-O, with humidity and O2 control

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactContamination-safe humidification system without water panTouchscreen controllerFail-safe CO2 system for protecting the pH of cell cultures

CO2 incubators CBF-OZ, with cell therapy compartmentalization, humidity and O2 control

Suitable for routine cell cultivation applications and incubation tasks, also for complex approaches under hypoxic conditions. Models with additional O2 control are available.Anti-contamination concept with 180 °C hot air sterilizationCO2 sensor with single-beam infrared technologySeamless inner chamber made of stainless steelFanless interior with Venturi CO2 gas mixing nozzleInternal data logger, measured values can be read out via USBTroubleshooting system with visual and acoustic alarmsInterfaces: Ethernet, USB, zero-voltage alarm contactContamination-safe humidification system without water panTouchscreen controllerFail-safe CO2 system for protecting the pH of cell culturesInner door divided into 8 parts with cell therapy compartmentalizationStainless steel inner door with 8 separate glass doors4 shelf levels with 8 insertsIndividual inserts can be pulled out completelyEach level is physically separated by an additional partition wall