LLG Catalogue

The extension kit is suitable for shaking 12 bottles or flasks. Maximum load: 3 kg. With 2 side arms for 6 clamps each. Supplied with 4 clamps.

Wide range of filters available on request.

This device is the innovative solution for the simultaneous and continuous detection of up to five gases. A combination of more than 25 sensors allows flexible solutions to individual monitoring tasks. The device can be equipped with three electrochemical, and two catalytic bead, infrared or photoionisation sensors. It is the ideal companion in a great number of applications where reliable monitoring of oxygen, toxic and combustible gases and vapors in ambient air is necessary.Basic unit with rubber-boot, carrying strap, calibration adapter, water and dust filter. In order to get a fully operational unit, a power pack and up to 5 sensors have to be ordered. And, optionally, a built-in pump or a datalogger can be ordered.SpecificationsTemperature: Pressure: Humidity:-20 ... +55 °C, short-term -40 ... +60 °C 700 ... 1300 hPa 10 ... 95 % r.F.Alarms (visual/audible):360° flashing LEDs / 100 dB(A) at 30 cmCharging time:3.5 to 7 hours, depending on battery typePump mode:maximum hose length of 45 mDimensions (W x H x D):150 x 140 x 75 mmWeight (basic unit/battery):600 g / 490 g (3,0 Ah), 730 g (6,0 Ah)Ingress protection:IP 67Approvals:ATEX, MED, CSA, IECEx

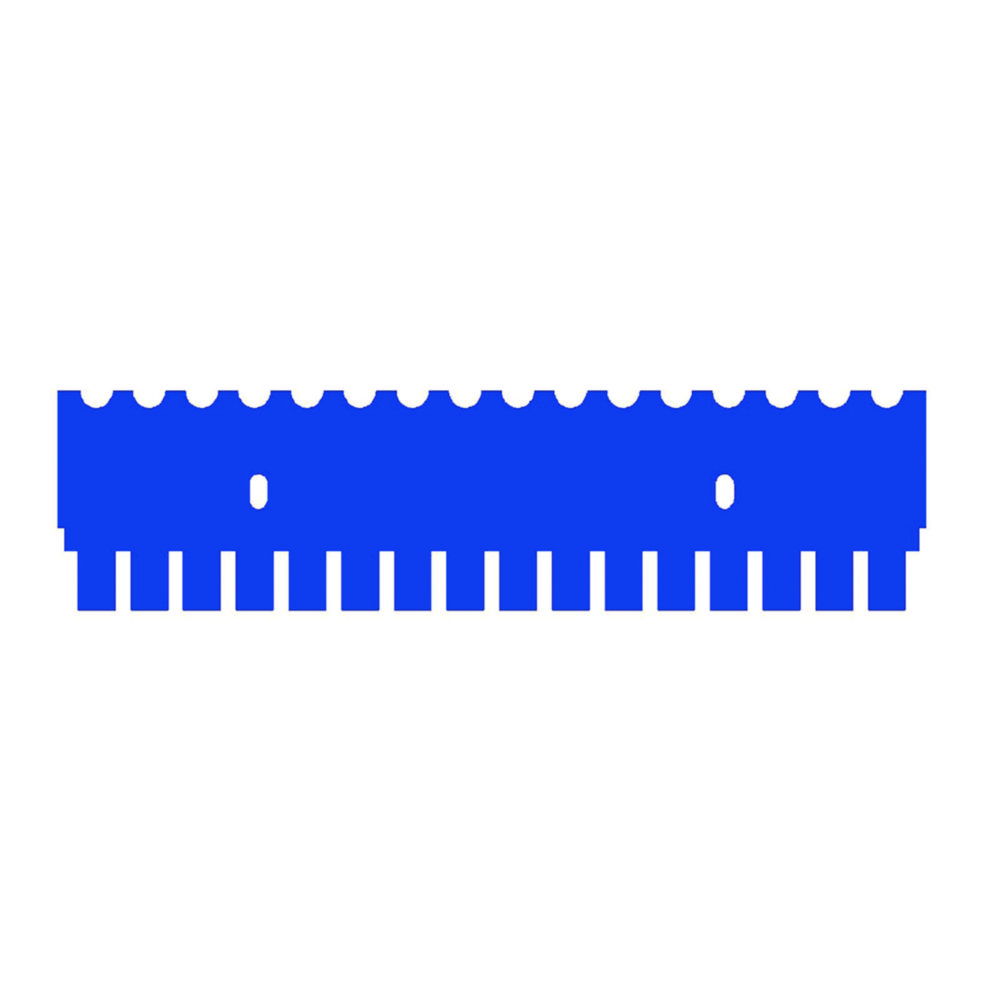

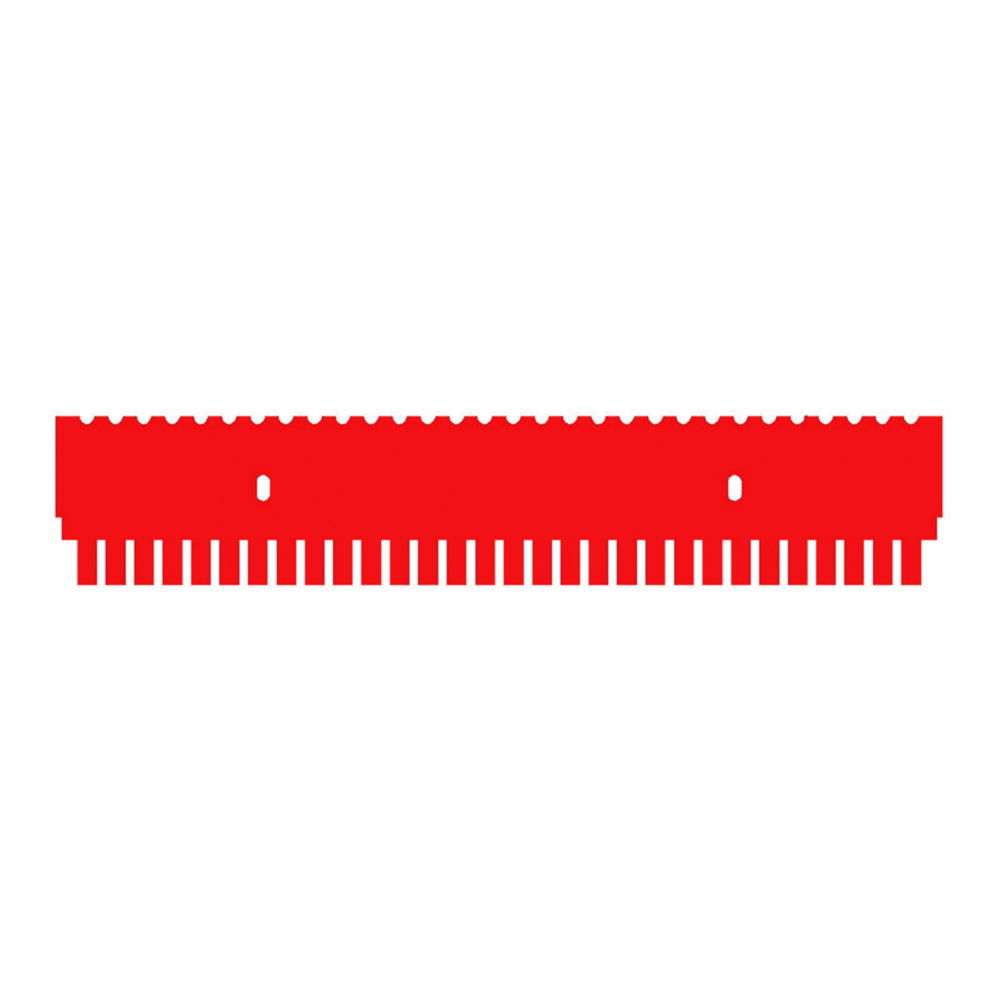

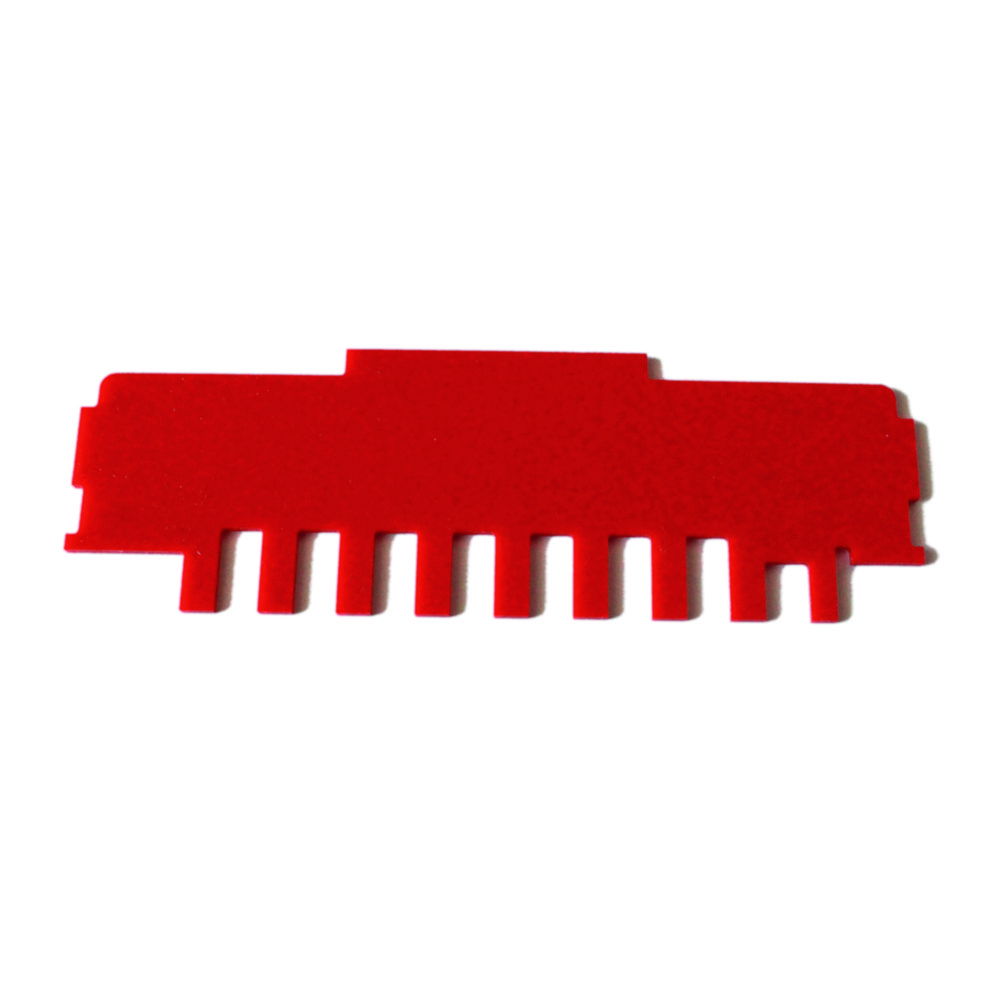

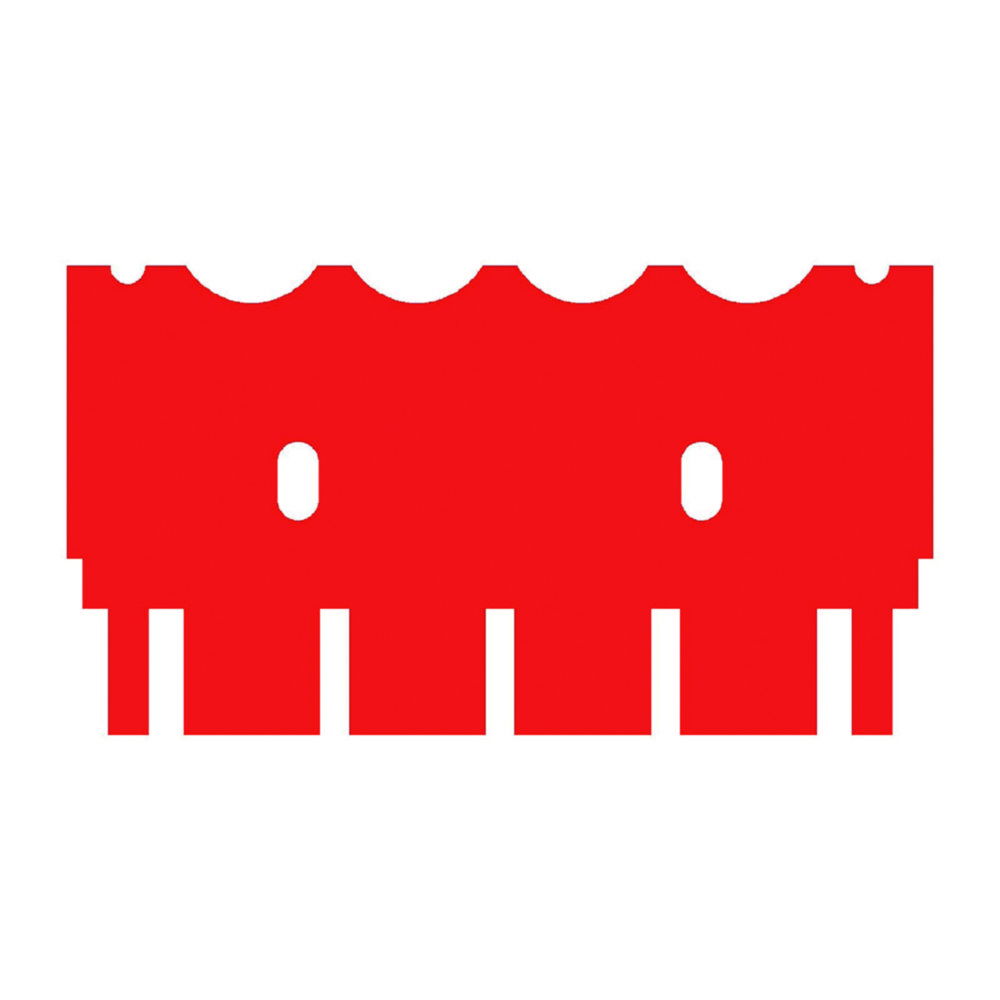

MC = Multichannel compatible with consecutive loading.MCSS = Multichannel compatible with alternated loading - every second well

MC = Multichannel compatible with consecutive loading.MCSS = Multichannel compatible with alternated loading - every second well.

MC = Multichannel compatible with consecutive loading.

MC = Multichannel compatible with consecutive loading.

MC = Multichannel compatible with consecutive loading.

MC = Multichannel compatible with consecutive loading.

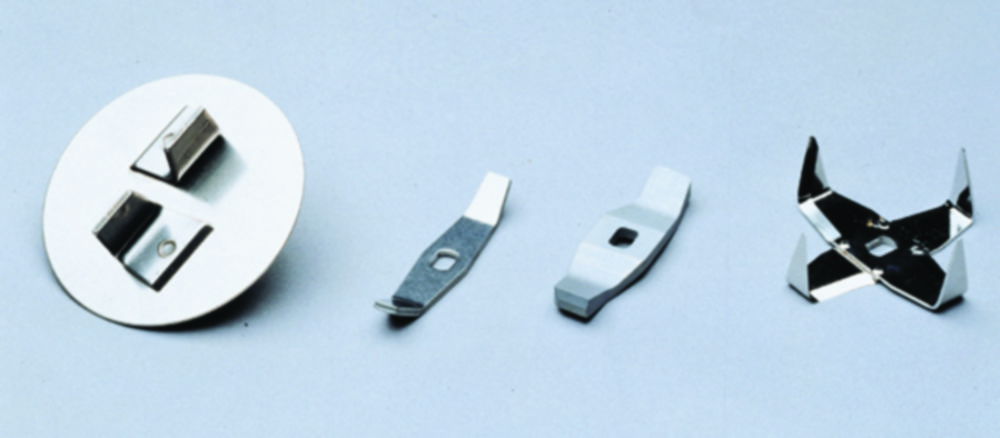

A 10.1 Cutter, stainless steel: For most brittle materials with a Mohs hardness up to 5.A 10.3 Cutter, hard metal: Made from tungsten carbide for hard materials with a Mohs hardness up to 9.A 10.2 Star-shaped Cutter, stainless steel: For specific lightweight materials like paper, dried plant parts, plastics and for smooth-elastic materials.A 10.4 Grinding chamber reduction: For small grinding volumes.

A 11.1 Spare beater: For pulverising substances with a Mohs hardness up to 6.A 11.2 Cutter: For pulverising soft, fibrous grinding materials.A 11.3 Beater, hard metal: For pulverising substances with a Mohs hardness up to 9, chrome-carbide coatedA 11.4 Grinding container, 250 ml: Made of polycarbonate with stainless steel inlet. Not suitable for cooling with N2, only applicable with double beater A 11.6.A 11.5 Spare grinding container, 80 ml: Made of Tefcel (PTFE, glass faser-reinforced) with stainless steel inlet. Excellent resistance to chemicals and low temperatures (-200 °C).A 11.6 Dubbel beater: For use up to Mohs hardness 3. Only applicable with grinding chamber A 11.4.A 11.7 Funnel: Prevents splashing by pouring in liquid nitrogen in the grinding chamber A 11.5.

Set of rings H 240: To cover the heating bath.Intermediate base H 159: Allows insertion of vessels into the bath, without affecting the stirrer motion.

For swing out rotors and buckets.