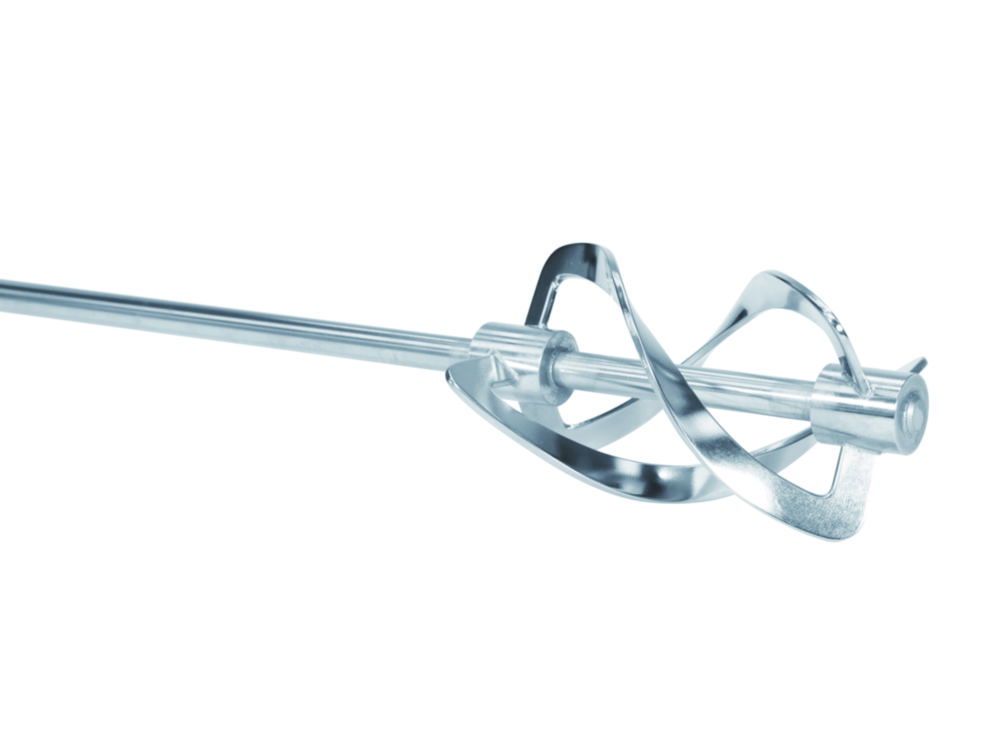

Spiral stirrer, stainless steel 1.4571

Generates axial flow. Medium is conveyed from the bottom upwards. For homogeneous mixing and heat exchange of medium to high viscosity media. Recommended for medium speed operations.

Stands

Floor stand BS 1 with angled foot, plastic-coated, stand rod Ø 34 x 1000 mmFloor stand BS 2 with angled foot, plastic-coated, stand rod Ø 34 x 1500 mmFloor stand BS 3 with angled foot 600 mm, completely made of stainless steel, stand rod Ø 34 x 1000 mmWall bracket WSRod diam. 34 x 1000 mm, clearance from wall: 200 mm.

Stirrer Shafts with One Paddle, PTFE

PTFE-jacketed stainless steel shaft, paddle completely made of PTFE with two 45° angled blades. Universal chemical resistance since the product is only exposed to PTFE. Temperature resistance: from -200 to +250 °C. The product is sucked bottom-up, very good axial flow with low shear force.

Turbine stirrer for Overhead Stirrers

These impellers are recommended for applications which require an average speedFor mixing products with average viscosity up to <500mPasIdeal for gassing of liquidsThese impellers create a radial flow

Turbine stirring rotors, 3-blade with guide ring, stainless steel 1.4305

The 3-blade turbine stirring rotor produces axial flow; the guide ring surrounding the blades reduces shear forces, and offers protection when contacting the wall or bottom of the vessel. Recommended for medium to high speed operations.