Grinding balls, hardened, stainless steel

Grinding balls are available in different materials.Grinding balls are also offered in the diameters 0.1 mm to 3 mm (to achieve a fineness down to the nanometer-range).

Grinding balls, hardmetal tungsten carbide

Grinding balls are available in different materials.Grinding balls are also offered in the diameters 0.1 mm to 3 mm (to achieve a fineness down to the nanometer-range).

Grinding balls, silicon nitride

Grinding balls are available in different materials.Grinding balls are also offered in the diameters 0.1 mm to 3 mm (to achieve a fineness down to the nanometer-range).

Grinding balls, sintered corundum

Grinding balls are available in different materials.Grinding balls are also offered in the diameters 0.1mm to 3mm (to achieve a fineness down to the nanometer-range).

Grinding balls, zirconium oxide

Grinding balls are available in different materials.Grinding balls are also offered in the diameters 0.1 mm to 3 mm (to achieve a fineness down to the nanometer-range).

Grinding bowls for mini mill PULVERISETTE 23

Grinding bowls and balls are also offered in zirconium oxide, as well as grinding balls in 15 mm diameter.

Grinding bowls for planetary ball mills PULVERISETTE 5 / 6 classic line

Grinding bowls 80 ml: One grinding bowl holder can hold either 2 x 80 ml bowls or 1 x 80 ml bowl together with a grinding bowl adapter mounted one on top of the other.Grinding bowls Agate and Tungsten carbide in a steel casing.Special gassing lids for grinding in an inert atmosphere and for mechanical alloying as well as the GTM-system (Gas pressure and temperature measuring system) for continuous measurment of gas pressure and temperature are available.

Grinding bowls for planetary micro mill PULVERISETTE 7 premium line

Grinding bowls in steel casing.Special gassing lids for grinding in an inert atmosphere and for mechanical alloying as well as the EASY GTM - Gas pressure and temperature measuring system, for controlling the grinding process due to continuous measurement of gas pressure and temperature are available.

Grinding bowls for planetary mill PULVERISETTE 5 premium line

Grinding bowl in steel casing.One grinding bowl holder can hold either 2 x 125-150 ml bowls together with a stacking ring or 1 x 125-150 ml bowl with a grinding bowl adapter mounted one on top of the other.Special gassing lids and screw-on grinding bowl lids for grinding in an inert atmosphere and for mechanical alloying as well as the EASY GTM Gas pressure for controlling the grinding process due to continuous measurement of gas pressure and temperature and for grinding in inert gas are available.

Grinding Jars for Mixer Mill MM 400

With screw cap.Simple and safe handlingDust and air-tightSuitable for wet and cryogenic grinding

Grinding Jars for Mixer Mill MM 500

With screw capScrew-Lock jars in sizes up to 125 ml, pressure-tight up to 5 bar

Grinding jars for planetary ball mill BM40

Grinding jars made of stainless steel, agate, sintered aluminium oxide, zirconium oxide and tungsten carbide have a stainless steel casing for safety reasons.

Grinding mill, A 10 basic

Newly designed batch mill for grinding of hard, brittle, soft and fibrous materials for volumes up to 50 ml. Because samples may be embrittled directly in the grinding chamber; tough, oily and aqueous samples can also be grinded. During development of the mill, particular emphasis was placed on safety. The mill will only start when the lid is closed and it can only be opened at standstill. A quick stop feature further increases the safety of user.Digital timerCounter: Display of grinding timeInterval operationBrushless motor for long life and low noiseIntegrated cooling connectionsError Code DisplayEasy handling with keypadsEasy exchangeable beater/cutter for a variety of applicationsGrinding chamber reduction for small sample amounts ( included with delivery)Easy opening and closing of the lid with a bayonet lock

Grinding mill, A11 basic

Batch mill for 2 different grinding procedures:Impact grinding of hard, brittle or non-elastic grinding materials with high-grade stainless steel beater. This beater can be used for a Mohs hardness up to 6 (incl. with delivery). Cutting grinding for pulverizing soft, fibrous materials with a cutting blade (not incl. with delivery).Moist and gluey materials can be pulverized by adding waterGrinding chamber made of Tefcel (PTFE, glass fibre-reinforced) with stainless steel inlet (1.4571), useful volume 80ml (incl. with delivery). For embrittlement of grinding materials with liquid nitrogen in the grinding chamberOptionally, a 250ml grinding chamber is availableAccessories please order separately.

Grinding set for mortar grinder PULVERISETTE 2

Mortars and pestles are also available in sintered corundum hardmetal tungsten carbide and zirconium oxide.

High Energy Ball Mill Emax

The Emax is an entirely new type of ball mill for high energy milling for medium-hard, hard, brittle and fibrous materials. The combination of high friction and impact results in extremely fine particles within the shortest amount of time. Thanks to the cooling system with water, the high energy input is effectively used for the grinding process without overheating the sample. The Emax is capable of continuous grinding operation without interruptions for cooling down. The high energy input in combination with the unique cooling system provides perfect conditions for effective mechanical alloying or grinding down to the nanometer range.Speed of 2000 rpm allows for ultra-fast and fine pulverization of the sampleControlled water cooling allows for continuous operation without cool down breaksTemperature-controlled grindingNarrow particle size distribution thanks to special jar design which improves mixing of the sample10 combinations of grinding parameters storableOperation with 2 grinding jars with integrated safety closureRange of jar materials allow for contamination free grindingAccessories on request.

Knife mill HM100

The HM100 knife mill is used for grinding soft, medium-hard, brittle and fibrous materials. Especially suitable for samples with a high water, oil or fat content. The 2 knives are driven by a 900 W motor to achieve a reliable grinding result. Suitable for applications in agriculture, biology, medicine and food technology.For soft, elastic, fibrous, aqueous, oily or fatty samplesElectronically controlled speedSamples are grinded in only 10 to 30 secondsUp to 700 ml sample volumeAutoclavable grinding vesselsGrinding vessels available in various materialsCutting knives with 2 stainless steel and titanium blades availableEasy operationQuick startCoarse and fine grinding in one stepInterval, reverse and manual mode availableScope of supply: Knife mill, 1 l grinding vessel made of plastic (autoclavable), lid, stainless steel knife

Knife mill PULVERISETTE 11

For reproducible homogenisation of all common samples in food or feed testing, pharmaceuticals, chemicals and many other applications. The quietly operating knife mill is ideal for gentle grinding and homogenisation of moisty, oily and greasy as well as dry, soft, medium-hard and fibrous samples within seconds.Motor power up to 1250 WattVariable speed setting with turbo functionStandard, reverse and interval operationKnife blades with 4 cutting edges, up to 56000 cuts per minuteFeed quantity up to 1400 ml (depending on material)Average grinding time only 30 seconds (depending on material)Fast cryogenic grinding20 SOPs can be stored, USB interface for SOP management and generation of grinding reportsEasy cleaningSample-contacting parts such as grinding containers, lids and knives can be autoclavedScope of supply: Knife mill, grinding container 1.4 l made of polycarbonate, standard lid, standard knife made of stainless steel

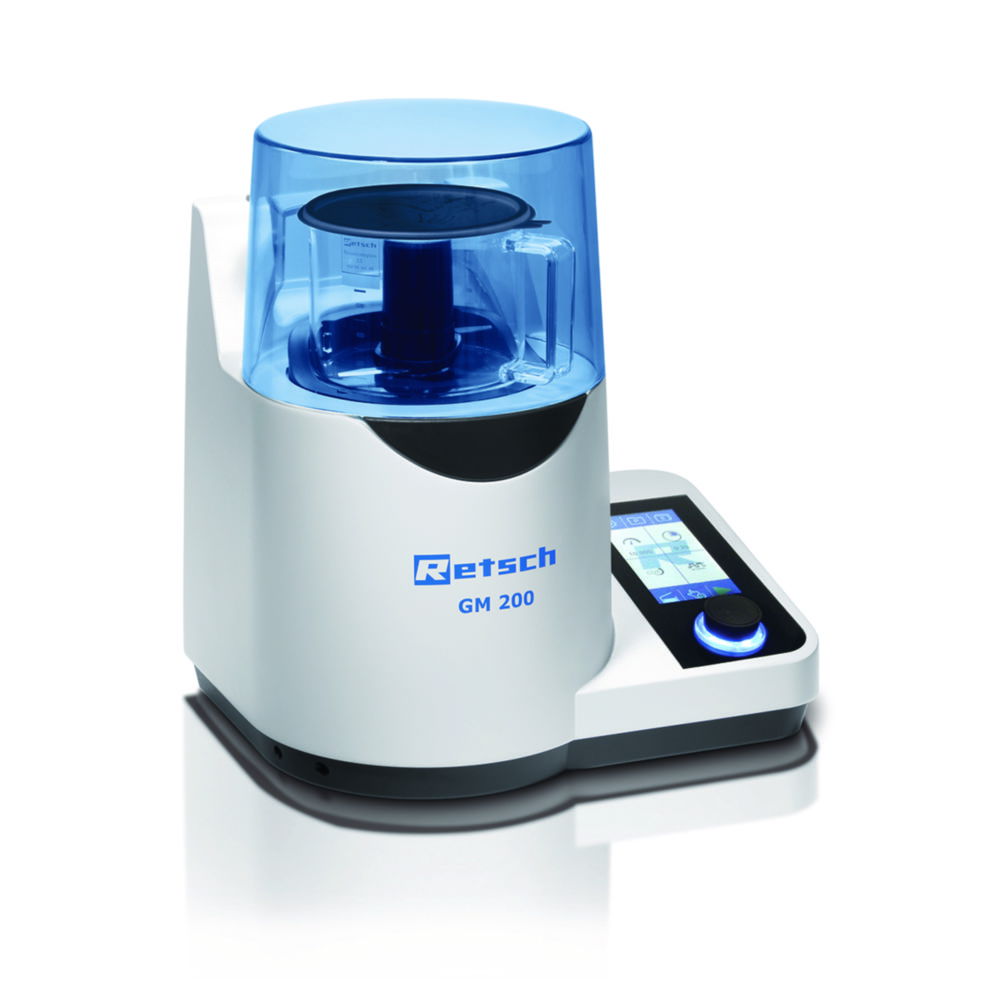

Knife Mills GRINDOMIX GM 200

The Knife Mills are suitable for the rapid and reproducible size reduction and homogenisation of food and feed materials. They can process substances with a high water, oil or fat content just as quickly and reliably as dry, soft and medium-hard products.Very fast and reproducible grinding and homogenisation of foodstuffsSpeed-controlled industrial motorAutoclavable grinding toolsBoost function allows short-term increase of speed up to 14000 rpmDigital display of grinding time and speedInterval operation possibleOptional gravity lid for automatic adjustment of grinding chamber volumeStorage of 4 program sequences possible8 parameter combinations can be storedScope of supply: knife mill, 1 l plastic container, standard lid, stainless steel knife

Knife Mills GRINDOMIX GM 300

The knife mills are suitable for the rapid and reproducible size reduction and homogenisation of food and feed materials. They can process substances with a high water, oil or fat content just as quickly and reliably as dry, soft and medium-hard products.Very fast and reproducible grinding and homogenisation of foodstuffsSpeed-controlled industrial motorAutoclavable grinding toolsDigital display of grinding time and speedInterval operation possibleOptional gravity lid for automatic adjustment of grinding chamber volume10 parameter combinations can be stored Scope of supply: knife mill, 5 l plastic container, standard lid, stainless steel knife, scraper