Autoclave deodorant Anabac®

Laboratories are very concerned about hygiene, cleanliness and comfort in the workplace. Try Anabac® autoclave deodorant balls to improve the working environment in the laboratory. These autoclave deodorant balls bring a discrete scent that speaks of cleanliness.

Autoclave deodorant Anabac® natural

Anabac® natural is an autoclave deodorant with 100% natural perfume, obtained from natural extracts. The ball dissolves without residue during autoclaving and the perfume is released. Autoclaving processes are not affected. Compatible with all autoclavesBiodegradableECOCERT certified according to the COSMOS standard

Autoclave thermometer

Durable bi-metal thermometer with a maximum registering pointer (red), moved up by the temperature measuring pointer, (black), to indicate the highest temperature achieved, and remains there until it is manually reset.Traceable to NIST StandardThreaded connection (1/4" NPT), screws directly into in-line processes, can be used to mount thermometer on included standWaterproof and pressurised, withstands autoclave cycles and has a removable protective silicone sleeve to prevent moisture from making contact with the dialConstructed from 304 stainless steel with a glass lens; withstands pressure, high temperatures and rustTested and inspected in the USAIncludes a multi-language (English, French, German, Italian, Portuguese, and Spanish) Statement of Accuracy and instructionsAvailable as an option with an individual Thermometer Calibration Report

Autoclaving baskets Nalgene™, PP

White. Suitable for cleaning and autoclaving laboratory articles. Smooth surface prevents scratching of plastic or glassware. With lid. Stackable.

Benchtop-Autoclaves HMT FA/-MA and -MB series

HMT 230/260 FA - for standard tasks:Certified according to regulation 93/42/EECAvailable in 2 sizes with a volume of 16 or 24 liters9 sterilization programs, fully automatic: 121 °C wrapped / unwrapped solid items; with or without drying, 135 °C wrapped / unwrapped solid items; with or without drying, Liquid program: 121 °C, 40 min.Controlled by a microprocessorSimple digital displayWater tankElectromechanical overheating protectionSafety valveMechanical pressure-dependent door lockReset/emergency buttonEasy maintenanceHMT 230/260/300 MA - versatile table-top autoclave:Certified according to regulation 93/42/EECAvailable in 3 sizes with a volume of 16, 24 or 40 litersPowerful integrated vacuum pump, an essential feature for sterilizing tubes and hollow components7 sterilization programs, fully automatic: 121 °C wrapped / unwrapped (vacuum), 134 °C wrapped / unwrapped (vacuum), Liquid and prion programs, Bowie-Dick testControlled by a microprocessorProgress indicatorInternal water tankElectromechanical overheating protectionElectronic overpressure protectionPressure safety valveMechanical pressure-dependent door lockReset/emergency buttonEasy maintenanceHMT 260/300 MB - premium table-top autoclave:Certified according to regulation 93/42/EECAvailable in 2 sizes with a volume of 24 or 40 litersPowerful integrated vacuum pump, an essential feature for sterilizing tubes and hollow components5 sterilization programs, fully automatic: Sterilization of wrapped items: 121 °C - 30 min.; 134 °C - 15 min., Sterilization of unwrapped items: 121 °C - 15 min.; 134 °C - 4 min., Individual temperature selection from 105° to 135 °C, Preset prion program3 test programs: leakage test, helix test, Bowie-Dick testControlled by a microprocessorEasy operation with a LCD displayDocumentation / data storage via SD card and printerDrying program, 1- 60 minutes4 literwater tank, to be filled manually or automatically (purified water)Various safety features, e.g. safety valve or pressure-dependent door lockWith modern design, easy maintenance

Biological Indicators Attest™ for Control of Steam Autoclaves

Biological control involves the use of indicators, which check whether all microorganisms were killed during the sterilisation process. The bio-indicators are unique, as they directly indicate how many microbial spores have actually been killed. Thanks to the reliability and quality of the information, the regular use of a bio-indicator can lead to an improvement in the performance of the sterilisation process and thus to better results.Features:No external laboratory is required for performance evaluationEasy handlingReasonable to use after repairs or maintenance of autoclavesApplication:Program 3.5 minutes, holding time at 121 °C or 134 °CAfter sterilisation, break the vial in order to bring the nutrient solution into contact with the spore stripResults in 48 hoursMeets EN ISO 11138 standard

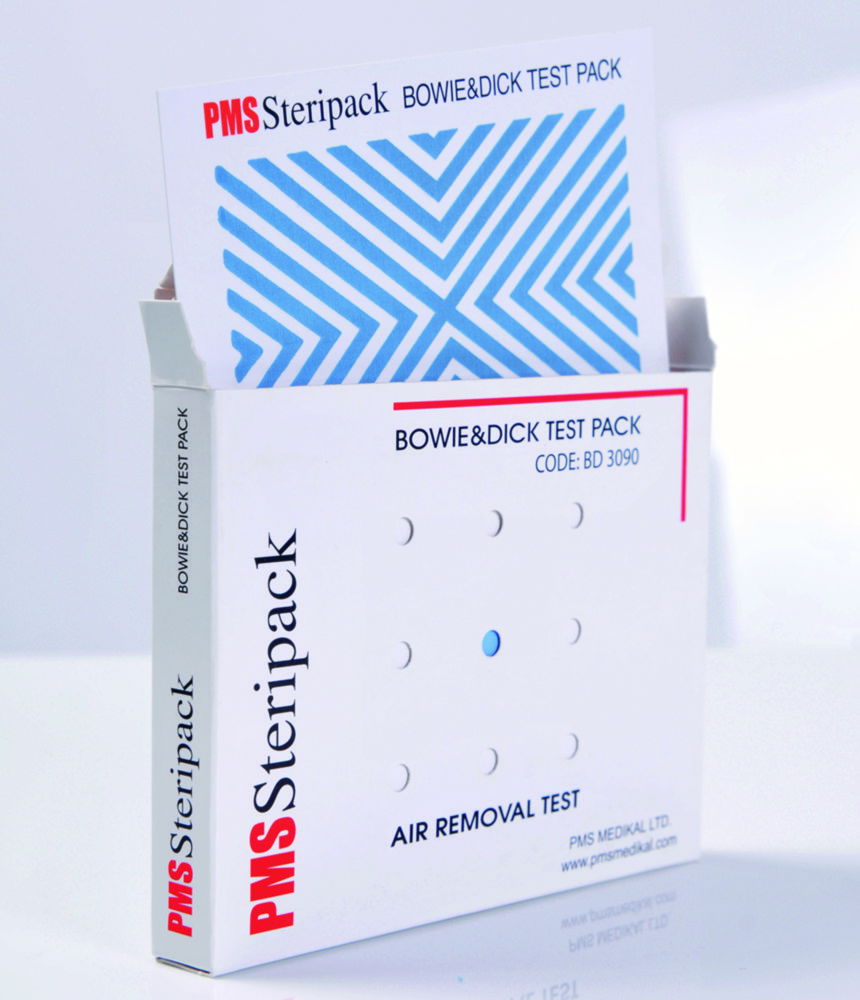

Bowie-Dick Test Pack

These Bowie-Dick Test Packs are pre-assembled, single use test packs designed to evaluate the performance of the air removal system of pre-vacuum assisted sterilisers in compliance with EN 285 and operating at 134 °C and 3.5 minutes. An indicator sheet printed with water based, non-toxic chemical indicator is placed in the center of each pack. The uniform colour change of the indicator after steam sterilisation indicates that all air was removed and replaced by steam. The backside of the indicator sheet contains fields to be filled out and it can be kept as a permanent record for traceability purposes.Disposable, pre-assembled and ready to use test packsDesigned for STEAM sterilization at 134 °C - 3.5 minutes.Clean and accurate indicator color changeIndicator sheet can be kept as a permanent recordValidated for 4 kg and 7 kg sterilisation loadManufactured in absence of lead or other heavy metals

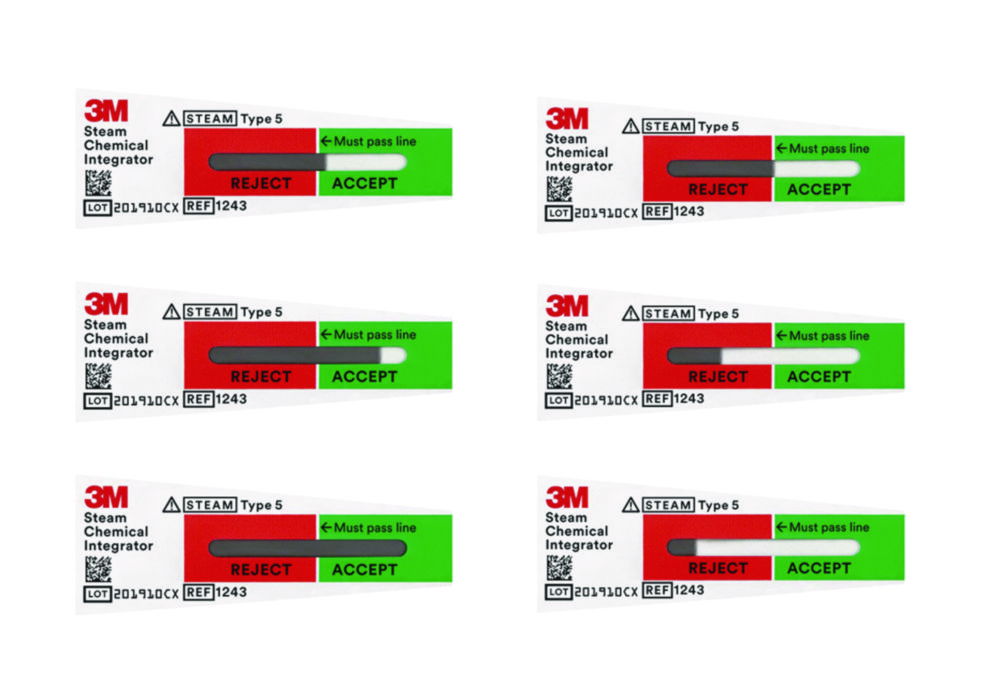

Chemical integrator for steam 3M™ Attest™ Type 5

Internal batch control monitor for steam sterilisation.ISO 11140-1:2014 Type 5 Integrating indicatorSimple evaluation within seconds using moving front ink technology with illuminated areas for ACCEPT (green) and REJECT (red)For use in all steam sterilisation cycles between 121 and 135 °CImproved efficiency with a scannable 2D barcodeShelf life 3 years

Digital horizontal autoclave Type AH

This autoclave is microprocessor controlled and monitored with 10 sterilisation programmes of which 4 are fixed and 6 are freely selectable and has bacteriological filters included by default.Operating temperature range 100 °C to 134 °COn request, also available with B ClassRS 232 interfaceFully automatic functionsWith water reservoir, pre-vacuum and dryingCase and lid shrouding are AISI 304 stainless steelSterilisation chamber, lid and sealing system are AISI 316 stainless steelElectrical heating with protected heating elementsSafety pressure valveSafety thermostatAutomatic steam controlled by Touch Screen microprocessorManual valves for emptying the sterilisation chamber and for draining steamEquipped with mesh stand on the chamber base and traysSupply requirements: 230 V 16 A single phaseOn request also available counter-pressure, steam generator or without vacuum and drying.

Digital vertical autoclaves, AES series

These autoclaves are microprocessor controlled and monitored with 10 sterilisation programmes of which 4 are fixed and 6 are freely programmable.Operating temperature range 100 °C to 134 °COn request also available with with vacuum pump and steam generatorAgar modus (40 °C to 80 °C)RS 232 interfaceTimerProgrammable auto-start (24 h)Fully automatic functionsCase and lid shrouding are AISI 304 stainless steelSterilisation chamber, lid and sealing system are AISI 316 stainless steelElectrical heating with protected heating elements in the interior of the chamberSafety pressure valveSafety thermostatAutomatic steam controlled by microprocessorManual valves for emptying the sterilisation chamber and for draining steamSupply requirements:AES-12 and AES-75: 230 V 16 A single phaseAES-110 and AES-150: 400 V + Neutral (3-phase)

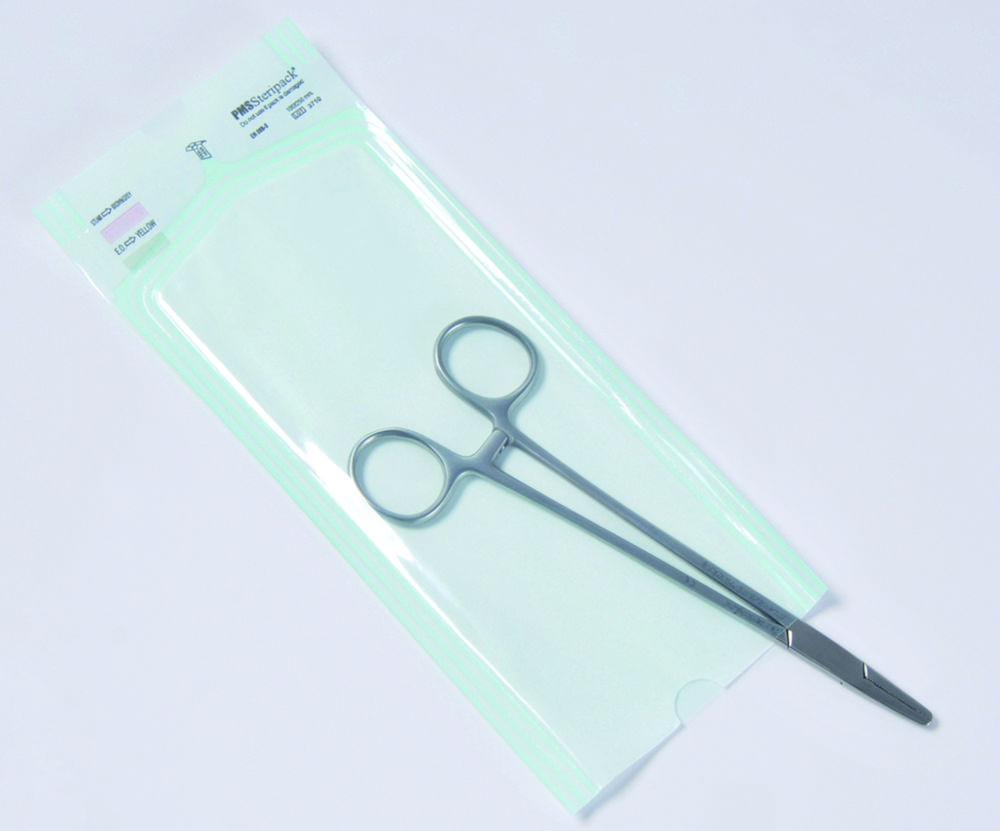

Heat-sealable sterilization pouches, flat

Heat-sealable sterilisation pouches as a packaging solution for sterilisation applications, ensure reliable protection of the medical device against contamination with bacteria from the time of sterilisation until use of the sterile medical device. The sterilisation pouches are constructed from transparent PET/PP multi-layer copolymer film and medical grade paper. Water based, non-toxic process indicators for steam and ethylene oxide sterilisation (complying with ISO 11140-1) are applied on the paper surface. This helps differentiating between processed and unprocessed packages. The sterilisation pouches are effective barriers against germs and according the requirements of ISO 11607, EN 868-5 and ISO 11140-1 standards.Reinforced film to avoid tearing during openingClean and accurate indicator colour changeTear, fibre-free opening and aseptic presentationTriple band seal for higher package integrityHeat-sealable sterilisation pouches as a packaging solution for sterilisation applications, ensure reliable protection of the medical device against contamination with bacteria from the time of sterilisation until use of the sterile medical device. The sterilisation pouches are constructed from transparent PET/PP multi-layer copolymer film and medical grade paper. Water based, non-toxic process indicators for steam and ethylene oxide sterilisation (complying with ISO 11140-1) are applied on the paper surface. This helps differentiating between processed and unprocessed packages. The sterilisation pouches are effective barriers against germs and according the requirements of ISO 11607, EN 868-5 and ISO 11140-1 standards.Reinforced film to avoid tearing during openingClean and accurate indicator colour changeTear, fibre-free opening and aseptic presentationTriple band seal for higher package integrity

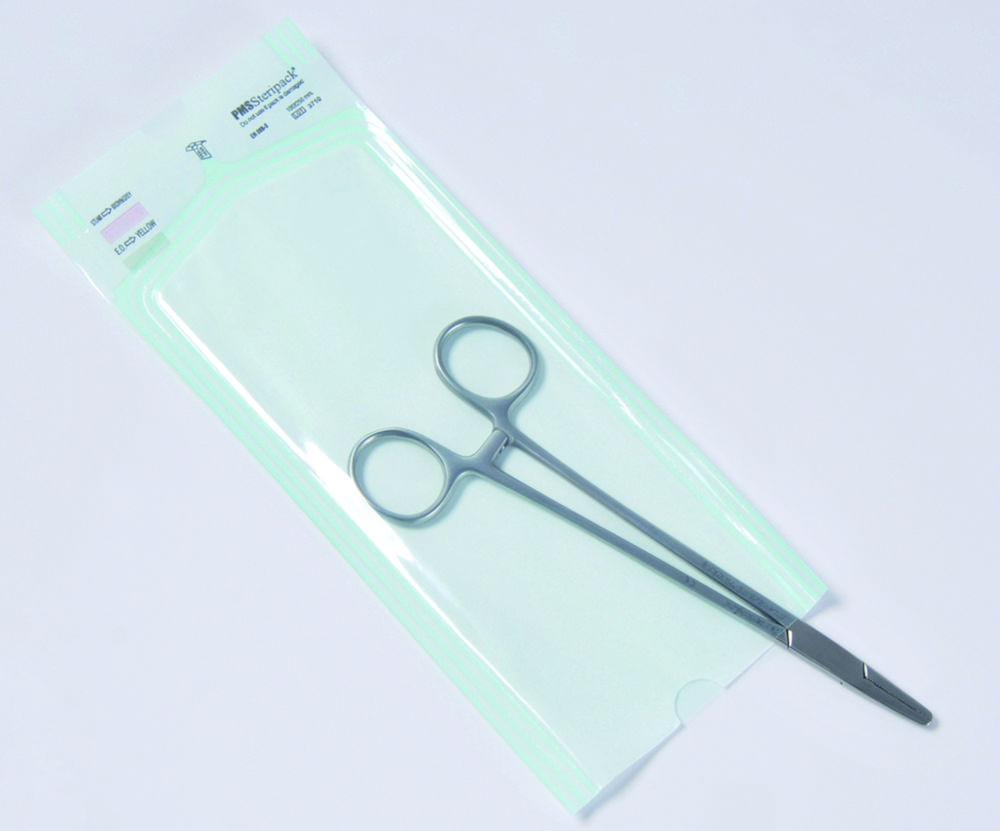

Heat-sealable sterilization pouches, with gusset

Heat-sealable sterilisation pouches as a packaging solution for sterilisation applications, ensure reliable protection of the medical device against contamination with bacteria from the time of sterilisation until use of the sterile medical device. The sterilisation pouches are constructed from transparent PET/PP multi-layer copolymer film and medical grade paper. Water based, non-toxic process indicators for steam and ethylene oxide sterilisation (complying with ISO 11140-1) are applied on the paper surface. This helps differentiating between processed and unprocessed packages. The sterilisation pouches are effective barriers against germs and according the requirements of ISO 11607, EN 868-5 and ISO 11140-1 standards.Reinforced film to avoid tearing during openingClean and accurate indicator colour changeTear, fibre-free opening and aseptic presentationTriple band seal for higher package integrityHeat-sealable sterilisation pouches as a packaging solution for sterilisation applications, ensure reliable protection of the medical device against contamination with bacteria from the time of sterilisation until use of the sterile medical device. The sterilisation pouches are constructed from transparent PET/PP multi-layer copolymer film and medical grade paper. Water based, non-toxic process indicators for steam and ethylene oxide sterilisation (complying with ISO 11140-1) are applied on the paper surface. This helps differentiating between processed and unprocessed packages. The sterilisation pouches are effective barriers against germs and according the requirements of ISO 11607, EN 868-5 and ISO 11140-1 standards.Reinforced film to avoid tearing during openingClean and accurate indicator colour changeTear, fibre-free opening and aseptic presentationTriple band seal for higher package integrity

Indicator tape for steam, hot air and gas sterilisation

Crepe paper, adhesive. With indicator. Colour changes according to DIN EN ISO 11140-1. Rolls of 50 m.

Laboratory autoclaves CertoClav Connect

Its versatility and compact construction make autoclaves especially interesting for small labs or they can be used as an optimal addition to a large autoclave.All models: Low-maintenance. No water connection required. Compliant with 2014/35/EU Low Voltage Directive, 2014/30/EU EMV Directive, 2011/65/EU Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment.Vertical models: Class N steam sterilisers. Venting procedure: free steam flow process or fractional flow procedure. A heater is integrated in the bottom of the chamber, but it is not exposed. Therefore, it cannot calcify. The autoclaves are easy to transport and location independent. All you need is a power supply and a mixture of tap water and demineralised water. Safeguarded by a multiple safety system. In aluminum models, it consists of an overpressure valve, a pressure valve, a safety lock inside the lid to prevent opening under pressure and the overpressure safety cavity. In stainless steel models, it consists of an overpressure valve, a pressure valve, a safety lock inside the lid to prevent opening under pressure and a two-bimetal safeguard to prevent overheating of the device.The fully automated, vertical laboratory autoclave is suitable for extended/ long- term cycles, material tests, HAST Test, Pressure Cooker Test, ICP-TM 650, culture media preparation, sterilisation of waste, unpackaged solids without hollow bodies, liquids, bottles, instruments, synthetic materials and rubber. It is operated with a 7-inch, robust, high-resolution touch screen. All operating steps are explained with videos directly on the CertoTouch. Individual sterilisation programs, which include several time and temperature steps can also be created directly on the CertoTouch. Once the autoclave is connected to the Internet via WLAN, it can be connected to the CertoCloud, an automatic process documentation. With this automatic documentation, the autoclave meets all GLP requirements.Automatic venting in fractional flow processElectric exhaust vapour valveElectronic safety lockTime and temperature individually editableEthernet, LAN, WiFiHeating integrated in the floorScope of supply: Autoclave, CertoTouch screen, instrument tray, PT100 media sensor, power cable, CertoCloud basic license

Laboratory autoclaves CertoClav MultiControl 2

Its versatility and compact construction make autoclaves especially interesting for small labs or they can be used as an optimal addition to a large autoclave.All models: Low-maintenance. No water connection required. Compliant with 2014/35/EU Low Voltage Directive, 2014/30/EU EMV Directive, 2011/65/EU Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment.Vertical models: Class N steam sterilisers. Venting procedure: free steam flow process or fractional flow procedure. A heater is integrated in the bottom of the chamber, but it is not exposed. Therefore, it cannot calcify. The autoclaves are easy to transport and location independent. All you need is a power supply and a mixture of tap water and demineralised water. Safeguarded by a multiple safety system. In aluminum models, it consists of an overpressure valve, a pressure valve, a safety lock inside the lid to prevent opening under pressure and the overpressure safety cavity. In stainless steel models, it consists of an overpressure valve, a pressure valve, a safety lock inside the lid to prevent opening under pressure and a two-bimetal safeguard to prevent overheating of the device.The PT100 sensor-controlled, vertical laboratory autoclave is suitable for extended/ long- term cycles, material tests, HAST test, Pressure Cooker Test, ICP-TM 650, culture media preparation, sterilisation of waste and biological hazardous substances (S2), unpackaged solids without hollow bodies, liquids, bottles, instruments, synthetic materials and rubber.With the control unit only programs that include just one time and one temperature step can be set. For programs that include several time and temperature steps, the PC software professional version is required.Microprocessor-controlledAutomatic venting in fractional flow processElectronic process controlAutomated error detectionProgrammable from 1 minute to 30 days and from room temperature to 140 °CControl unit with LCD displayUSB portPrinter port (RS232) for printing sterilisation protocolsHeating integrated in the baseScope of supply: Autoclave, MC2 control unit including instrument tray, power cable, PC software basic version