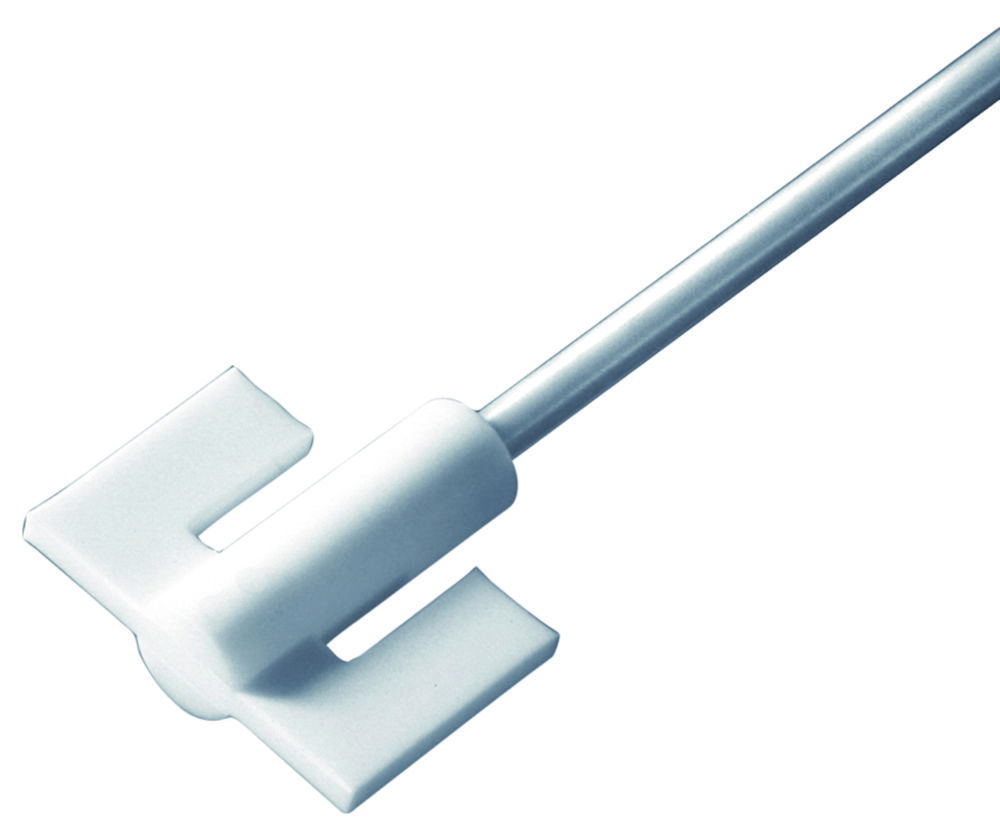

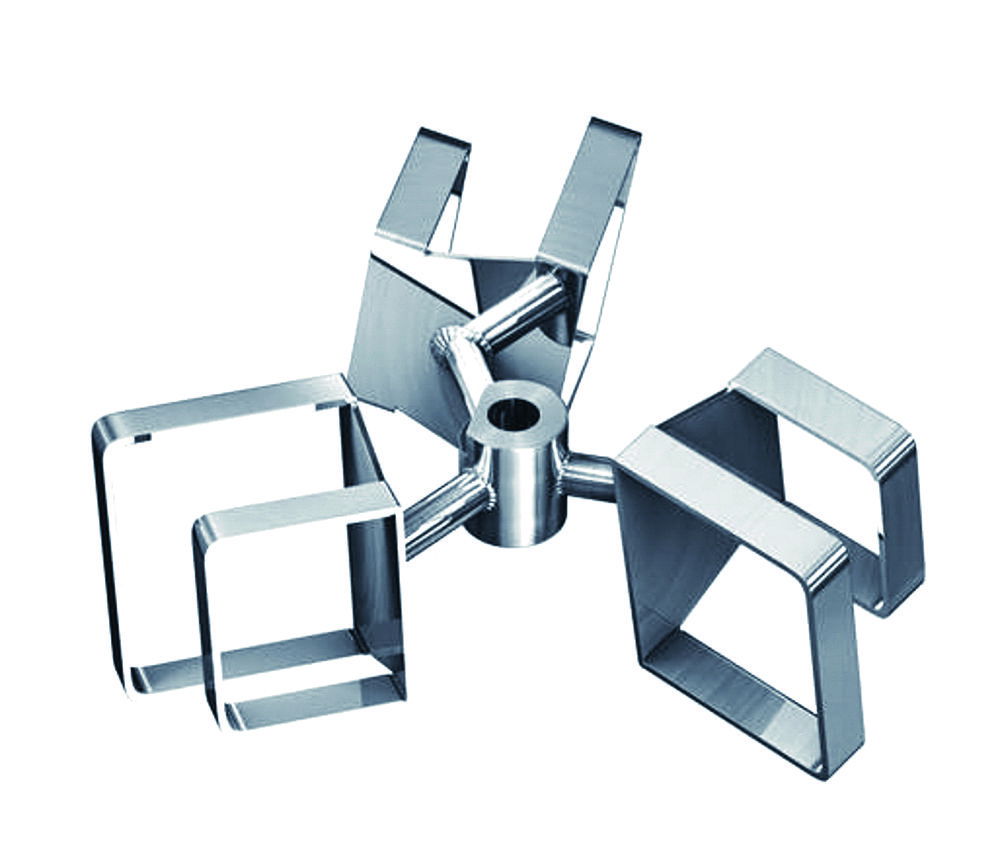

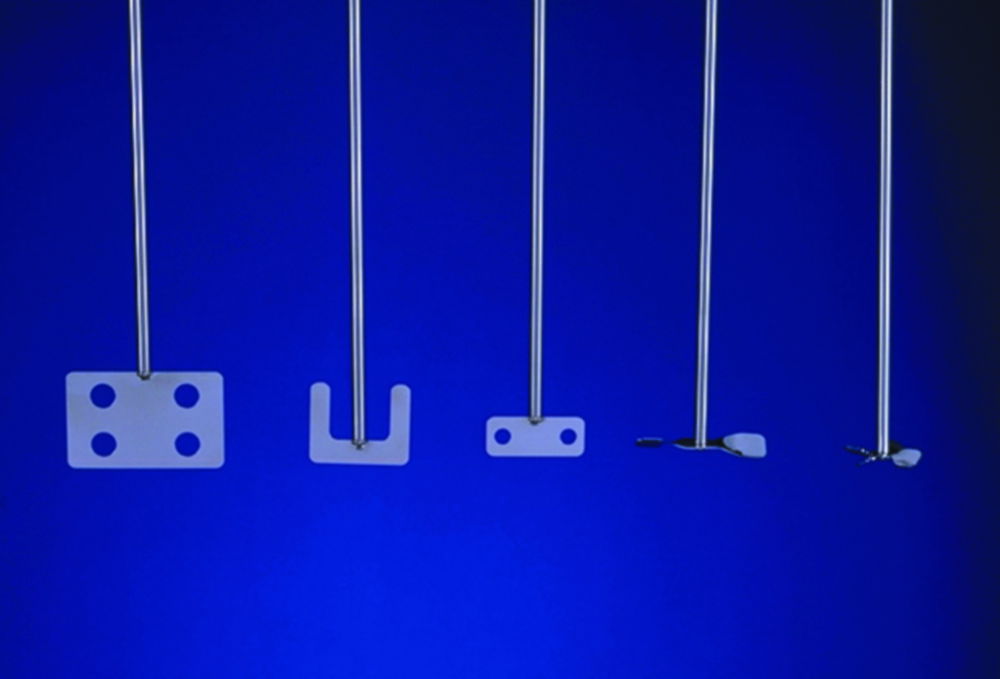

Additional Stirrer Blades for Bola Stirrer Shafts, PTFE

Useful extension to the existing range of Bola stirrer shafts. The additional blades can optionally be fixed in your preferred position on every stirrer shaft with diameter 8,10 or 16 mm (a flat spanner is included). The stirrer blades are entirely made of PTFE, the mounting devices are made of a special PTFE-compound. A high chemical and thermical (-200 to +250 °C) resistance is assured. This "building block system" allows the user to define a stirrer of their own special requirements.

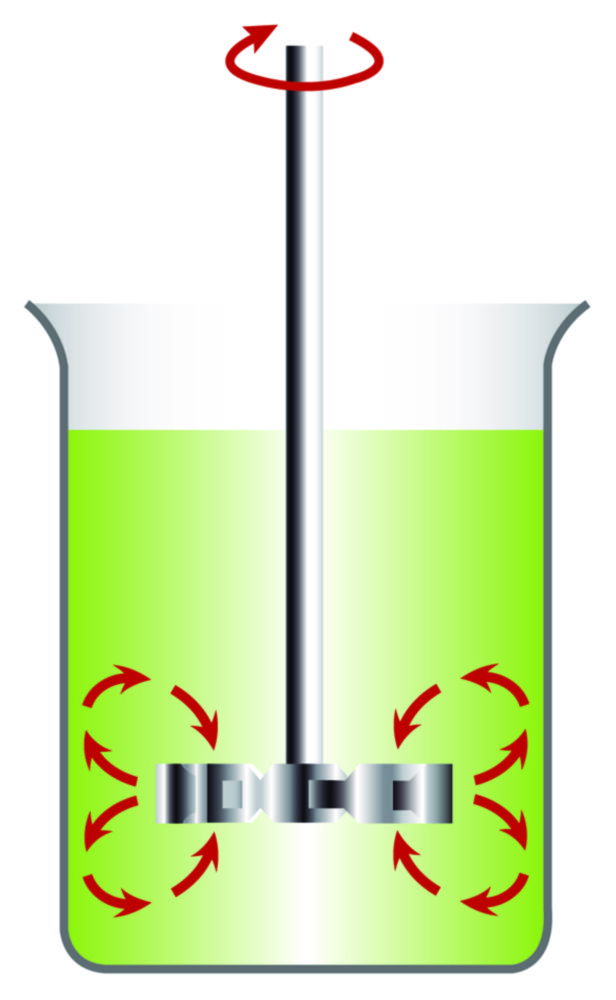

Anchor stirrer for Overhead Stirrers

These impellers are recommended for applications which require a low speedFor mixing products with medium or high viscosity

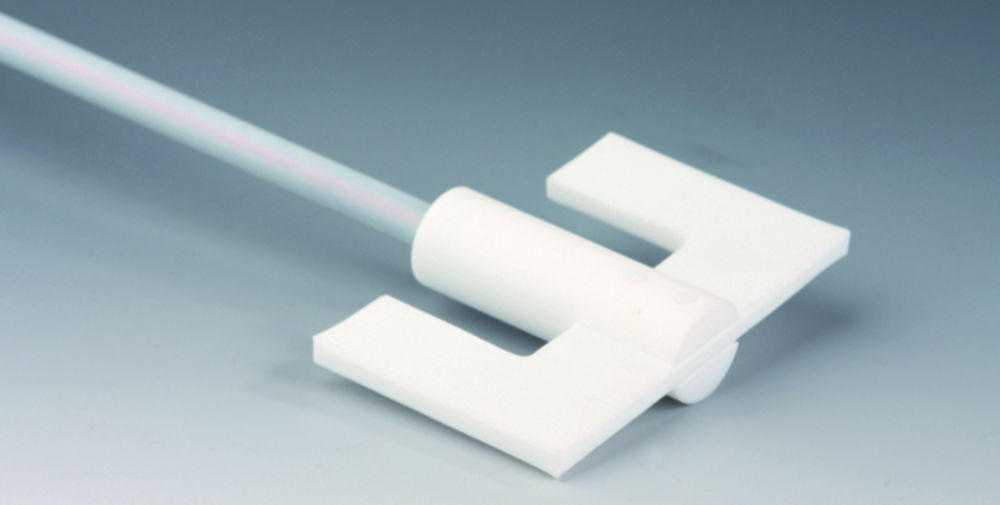

Anchor stirrer, PTFE

The stirrer shafts consist of a PTFE-jacketed, stainless steel shaft and a stirrer paddle made of solid PTFE. The stainless steel core assures stability of the stirrer shaft and allows safe attachment of the stirrer chuck. Thanks to the thick PTFE coat and the paddle made of solid PTFE, the medium will only come into contact with PTFE. High chemical resistance makes it almost universally suitable. PTFE is extremely nonstick so that residues are repelled from shaft and paddle. The stirrer shafts are similar in size to (KPG) glass stirring rods and are therefore interchangeable easily.Operating temperature: -200°C to +250°CAdditional sizes and accessories are available on request.Information on the mixing effects of the different stirring geometries can be found in the descriptions of the stainless steel stirring rotors.Recommended for low speed operations.Additional wings available on request

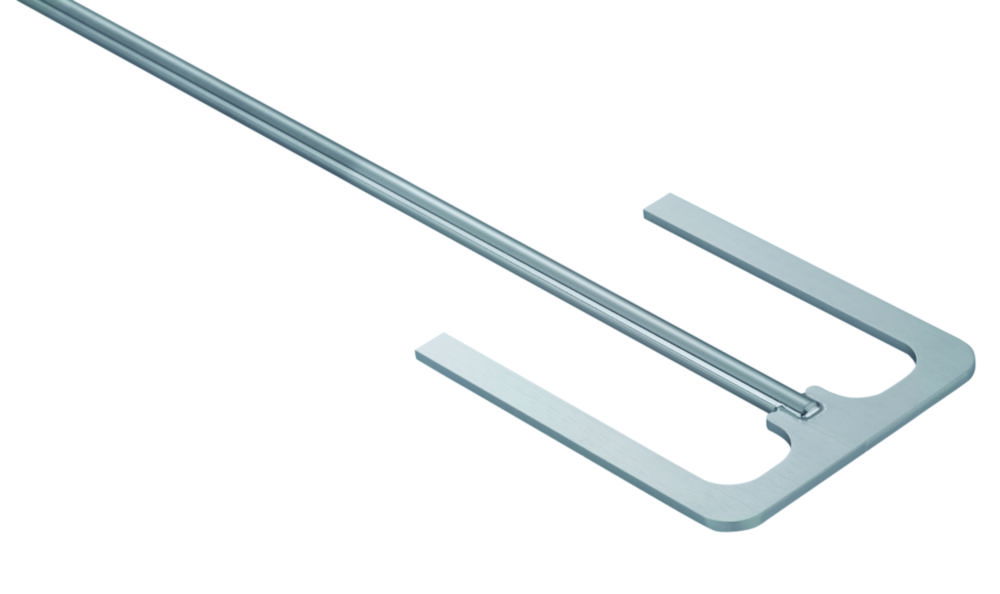

Anchor stirrers, stainless steel 1.4571

The anchor stirrers create a tangential flow and high shear forces between the vessel wall and stirring blades. Especially suitable for medium to high viscosity fluids. Recommended for low speed operations.

Anchor stirring rotors, stainless steel

The anchor-shape rotor creates a tangential flow and high shear forces between the vessel wall and stirring blades. This stirrer is especially suitable for medium to high viscosity fluids. Recommended for low speed operations.

Blade stirrer for Overhead Stirrers

These impellers are recommended for applications which require an average speedFor mixing products with average viscosityModels BR 12 and BR 14 come with collapsible blade for narrow neck vessels

Blade stirrer, stainless steel 1.4571

Generates a radial flow. For drawing the material to be mixed from the top and bottom. For aerating of low viscosity media and for homogenizing solids in liquids. Used at medium to high speeds.

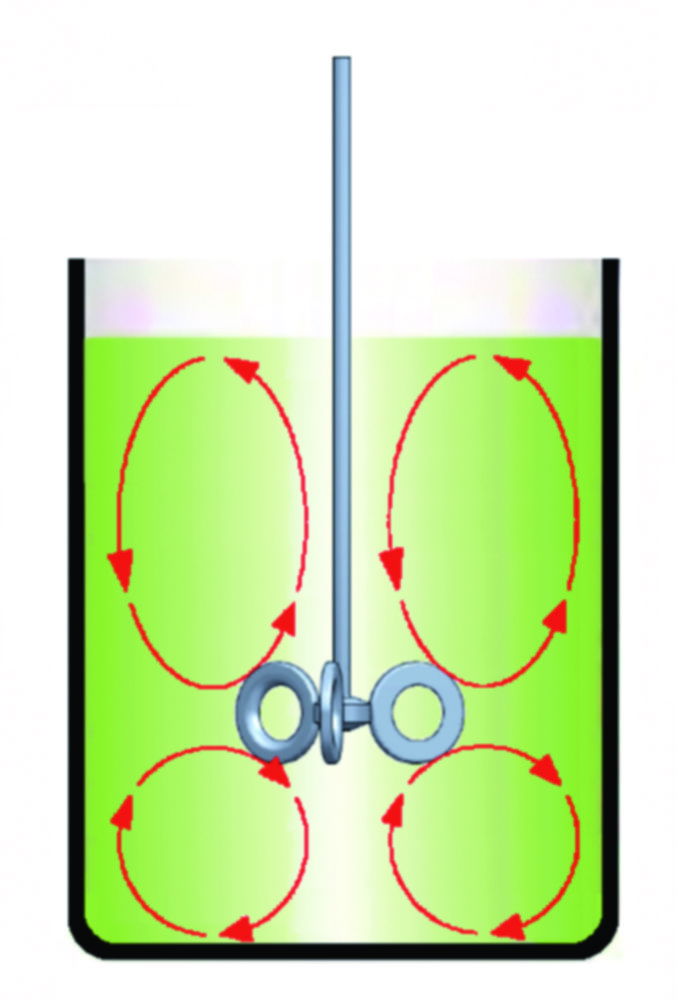

BuddeMix Stirring System 1 - 4

This novel stirring system has been conceived to mix low viscosity fluids as well as highly viscous media at slow speeds. Its special design creates inherent dynamic currents to produce perfectly homogeneous mixing results in very little time. Additional components like baffles, bottom bearings, etc. are not needed.Advantages at a glance:suitable for low to highly viscous fluidsstirs media containing solids and fibres without any difficultygentle, low-shear stirring, due to slow stirring speedconstant product temperature, with no heating effectshort mixing times as the entire contents of the container are agitatedno air addition, no foamingno baffles requiredlow gear wear due to balanced forcesminimal power consumption thanks to low speeds and short operation timeseasy cleaningmaterial no. 1.4404Particularly for potentially explosive atmospheres:a single stirring zone, near to the container base, ensures easy mixing of settled residues, e.g. in flow-through mixing containersno baffles required, thus no additional sources of ignitionCustomised shaft length possible. Fine polishing Ra 0.6 to 0.8 µm and/or material certificate available on request.

Centrifugal stirring rotors, 2-blade, stainless steel 1.4305

The folding blades of this 2-blade centrifugal stirring rotor open with increasing speed, allowing use with narrow-neck vessels. The stirring effect it provides is similar to a standard diagonal blade stirring rotor. Recommended for medium to high speed operations.

Compressed air powered stirrers, PLR, accessories

Connection couplings VK:Fixed-diameter connection for motor/magnetic coupling drive shaft and stirring rod. Suitable for use in potentially explosive atmospheres. Material No. 1.4404.Flexible glass stirring shaft couplings PK:For stirring tasks using glass stirring rods. Elastic connector between motor and stirring shaft. Provides exact alignment of motor and shaft, and evens out axial and height differences. Accepts 6mm to 10mm diameter shafts.Flexible glass stirring shaft couplings K:For stirring tasks using glass stirring rods. Elastic connector between motor and stirring shaft. Provides exact alignment of motor and shaft, and evens out axial and height differences. Accepts 6mm to 10mm diameter shaftsDouble-Cardan-Coupling DCK I:With 8mm dia. hexagonal input drive receiver and 6mm square socket drive output.

Crescent-shaped stirring rotors, PTFE

The stirrer shafts consist of a PTFE-jacketed, stainless steel shaft and a stirrer paddle made of solid PTFE. The stainless steel core assures stability of the stirrer shaft and allows safe attachment of the stirrer chuck. Thanks to the thick PTFE coat and the paddle made of solid PTFE, the medium will only come into contact with PTFE. High chemical resistance makes it almost universally suitable. PTFE is extremely nonstick so that residues are repelled from shaft and paddle. The stirrer shafts are similar in size to (KPG) glass stirring rods and are therefore interchangeable easily.Operating temperature: -200°C to +250°CAdditional sizes and accessories are available on request.Information on the mixing effects of the different stirring geometries can be found in the descriptions of the stainless steel stirring rotors.The semi-circular shape of the paddle is ideal for mixing in round-bottom flasks. The pivoting blade allows insertion into vessels with narrow necks and/or ground joints.

Cylinder oil

Resin-free and non-corrosive oil for lubrication of compressed air stirrers.

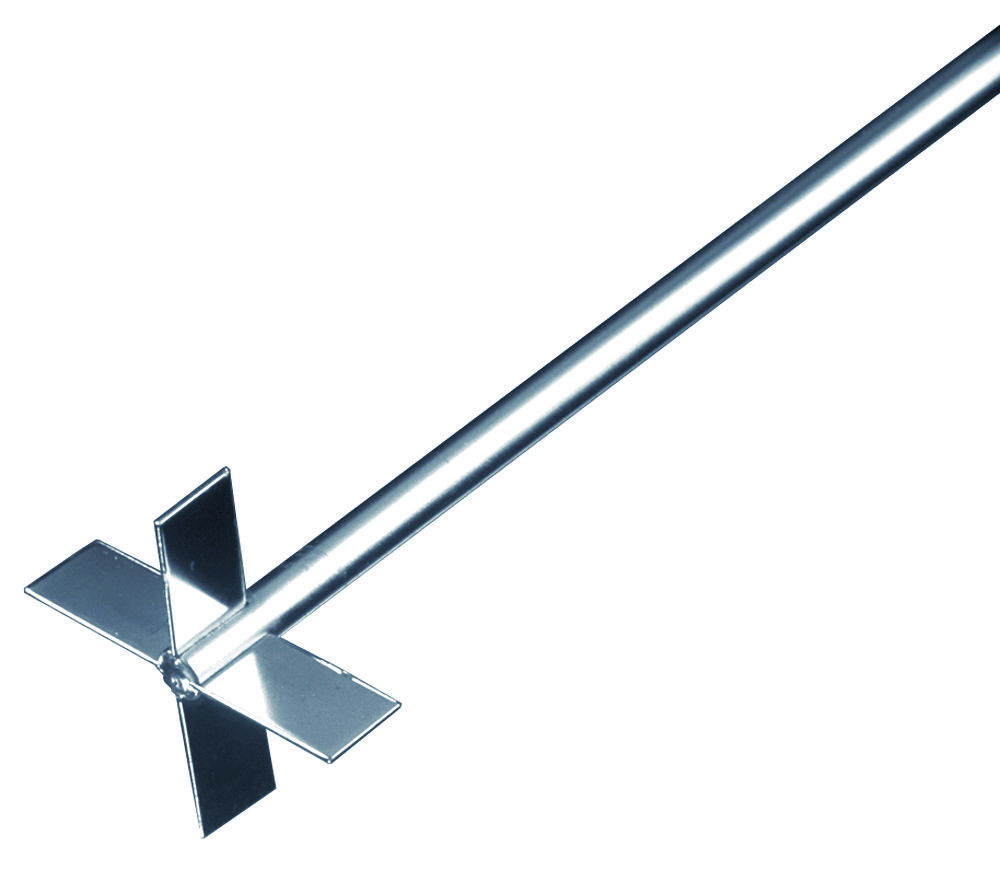

Diagonal blade stirring rotors, 4-blade, stainless steel 1.4404

The 4-blade diagonal blade stirring rotor provides axial flow and creates increasing shear forces at higher stirring speeds. Recommended for medium to high speed operations.Other sizes available on request.

Dissolver stirrers, stainless steel 1.4571

The dissolver stirrers create a radial flow with high turbulence. The mixture is drawn from top to bottom. High shear forces are created at the dissolver disk, which provides effective particle reduction. Recommended for medium to high speed operations.

Dissolver stirring rotors, stainless steel 1.4404

The dissolver stirring rotor creates a radial flow with high turbulence. The mixture is drawn from top to bottom. High shear forces are created at the dissolver disk, which provides effective particle reduction. Recommended for medium to high speed operations.

Finger-operated oiler OT

For manual lubrication of compressed air coming into the motor.

Half-moon stirrer for Overhead Stirrers

These impellers are recommended for applications which require an average speedFor mixing products with average viscosityModel HR 18 come with tilting agitator blades

Impellers VISCO JET®

The worldwide patented VISCO JET® Mixing System is the result of the so-called cone-principle. Turbulent flows are created at the taper end by acceleration, displacement and retardation. These flows advance through the stirred medium and result in the new dynamic mixing motion.One system for literally all mixing tasks for low to high viscosity mediaPatented cone-principle creates even at low speeds a turbulent flow which is unique to the VISCO JET®Even with high-viscosity media and gels which naturally do not mix by using common impellers you will observe an immediate flow through the entire beakerThis technology allows for de-gassing of gels while preventing air intake and foamingReduce process times significantly while performing the best mixing result everThe stirring systems are made of stainless steel or polyoxymethylene (POM).

Moebius stirrer, stainless steel 1.4571

Generates axial flow. For drawing the material to be mixed from above. For circulating and handling low to medium viscous liquids. Recommended for medium speed operations.

Overhead stirrer rotors, centrifugal paddle, PTFE

With PTFE-coated, stainless steel shaft.

Overhead Stirrer shafts

Stainless steel. Supplied as separate 8mm diameter shaft with tapped screwthread end onto which can be attached a choice of paddle types. Lengths as indicated.

Paddle stirring rotors, stainless steel

The paddle stirring rotor creates a tangential flow with minimum turbulence. Its design ensures a gentle action on sensitive products and good heat exchange. Recommended for low to medium speed operations.Other sizes available on request.