Adapter for polyamide test sieves

This adapter is to be used in combination with the clamping lid plexiglas, for test sieves 200 mm / 8" Ø (Cat. No. 9.826 404) for secure fixing of polyamide test sieves on Fritsch Sieve Shakers ANALYSETTE 3 PRO and SPARTAN.

Adapters for test sieves Ø 200 mm

Allows the use of existing and non-NEXOPART sieves.

Adapters for test sieves Ø 203 mm

Allows the use of existing and non-NEXOPART sieves.

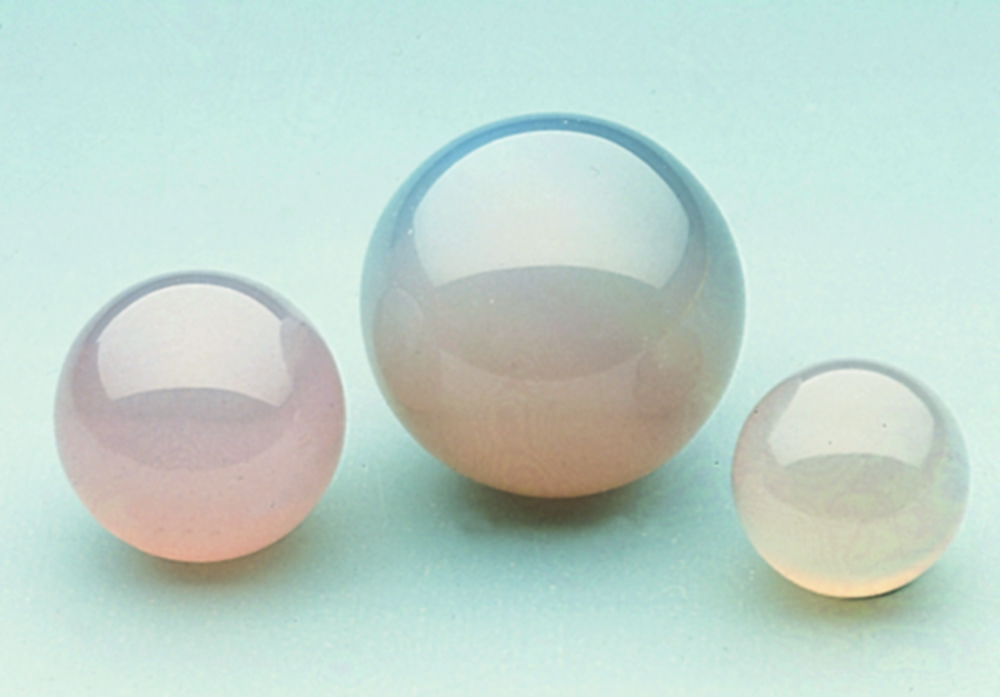

Agate Grinding bowls for Ball-mills, with lid and PTFE ring

For gentle grinding and rubbing. Grinding bowls with 80 ml are stackable. Please order stacking ring separately.

Air jet sieve machine e200 LS eControl BASIC

Air jet sieve machine for separating, fractionating, and determining the particle size of fine to very fine powders. The device delivers precise measurement results and ensures high reproducibility. It is also characterised by its user-friendly and simple operation via the touch display.Stainless steel cast housingReduced noise level thanks to new intake silencerDiagnostic tool with self-monitoring of all electronic componentsSuitable for sieve diameter 76 mm, 200 mm, and 203 mmMeasuring size 20 µm to 4 mm (sieve Ø 200/203 mm), 10 µm to 2.5 mm (sieve Ø 76 mm)Automatic sieve detection (RFID)Automatic underpressure controlFast, simple evaluation of the results (in tabular form)Balance communication via RS-232 interfaceCentral parameter management of all sievesScope of supply: Air jet sieve machine, software version BASIC, sieve adapter, slottet nozzle, acrylic glass lid, suction silencer, hammer and brush, connection piece, power connection cable, operating manualPlease order vacuum cleaner separately.

Air jet sieve machine e200 LS eControl LITE

Air jet sieve machine for separating, fractionating, and determining the particle size of fine to very fine powders. The device delivers precise measurement results and ensures high reproducibility. It is also characterised by its user-friendly and simple operation via the touch display.Stainless steel cast housingReduced noise level thanks to new intake silencerDiagnostic tool with self-monitoring of all electronic componentsSuitable for sieve diameter 76 mm, 200 mm, and 203 mmMeasuring size 20 µm to 4 mm (sieve Ø 200/203 mm), 10 µm to 2.5 mm (sieve Ø 76 mm)Simple one-touch operationExternal vacuum cleaner can be integratedDisplay of underpressure (in Pa), sieving time, date, and timeManual underpressure controlScope of supply: Air jet sieve machine, software version LITE, sieve adapter, slottet nozzle, acrylic glass lid, suction silencer, hammer and brush, connection piece, power connection cable, operating manualPlease order vacuum cleaner separately.

Air jet sieve machine e200 LS eControl SECURITY

Air jet sieve machine for separating, fractionating, and determining the particle size of fine to very fine powders. The device delivers precise measurement results and ensures high reproducibility. It is also characterised by its user-friendly and simple operation via the touch display.Stainless steel cast housingReduced noise level thanks to new intake silencerDiagnostic tool with self-monitoring of all electronic componentsSuitable for sieve diameter 76 mm, 200 mm, and 203 mmMeasuring size 20 µm to 4 mm (sieve Ø 200/203 mm), 10 µm to 2.5 mm (sieve Ø 76 mm)Automatic sieve detection (RFID)Automatic underpressure controlFast, simple evaluation of the results (in tabular form)Balance communication via RS-232 interfaceCentral parameter management of all sievesAutomatic saving and printingSieve set management (SOP)Automatic backupRequirements for software validation as classified in ISPE GAMP 5, FDA 21 Part 11, compliant with EC GMP Annex 11Scope of supply: Air jet sieve machine, software version SECURITY, sieve adapter, slottet nozzle, acrylic glass lid, suction silencer, hammer and brush, connection piece, power connection cable, operating manualPlease order vacuum cleaner separately.

Air jet sieve machine e200 LS eControl ULTIMATE

Air jet sieve machine for separating, fractionating, and determining the particle size of fine to very fine powders. The device delivers precise measurement results and ensures high reproducibility. It is also characterised by its user-friendly and simple operation via the touch display.Stainless steel cast housingReduced noise level thanks to new intake silencerDiagnostic tool with self-monitoring of all electronic componentsSuitable for sieve diameter 76 mm, 200 mm, and 203 mmMeasuring size 20 µm to 4 mm (sieve Ø 200/203 mm), 10 µm to 2.5 mm (sieve Ø 76 mm)Automatic sieve detection (RFID)Automatic underpressure controlFast, simple evaluation of the results (in tabular form)Balance communication via RS-232 interfaceCentral parameter management of all sievesAutomatic saving and printingSieve set management (SOP)Automatic backupScope of supply: Air jet sieve machine, software version ULTIMATE, sieve adapter, slottet nozzle, acrylic glass lid, suction silencer, hammer and brush, connection piece, power connection cable, operating manualPlease order vacuum cleaner separately.

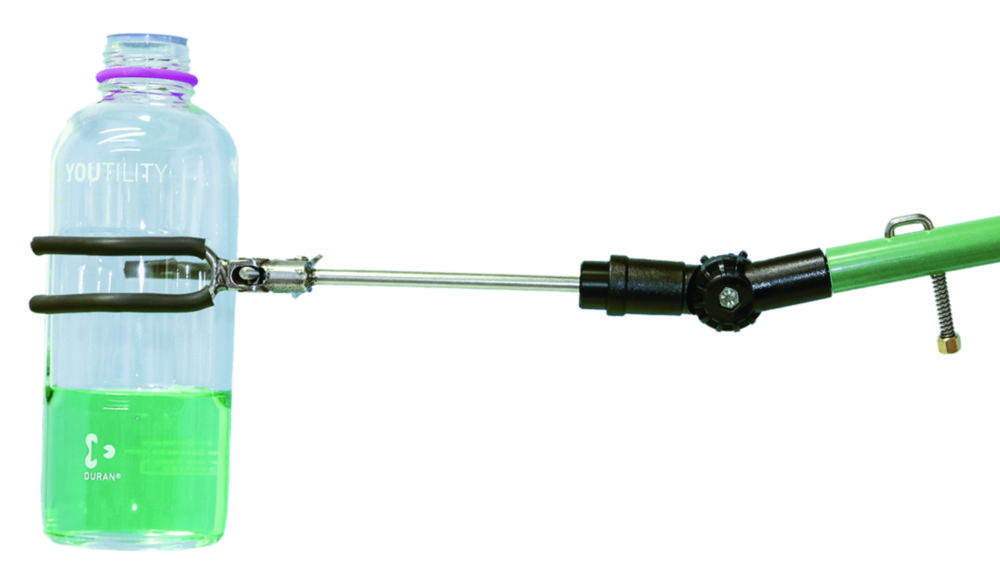

All purpose clamp for sample bottles, stainless steel

For various bottles with neck diameters from 10 to 80 mm and volumes of max. 1000 ml. With adjustable click-in angle from 0 to 180°.

All purpose clamp, stainless steel with silicon coating

For bottles or containers with a diameter of up to 110 mm. With 3 holder elements coated with a silicone tube for a very safe grip. With adjustable click-in angle from 0 to 180°.

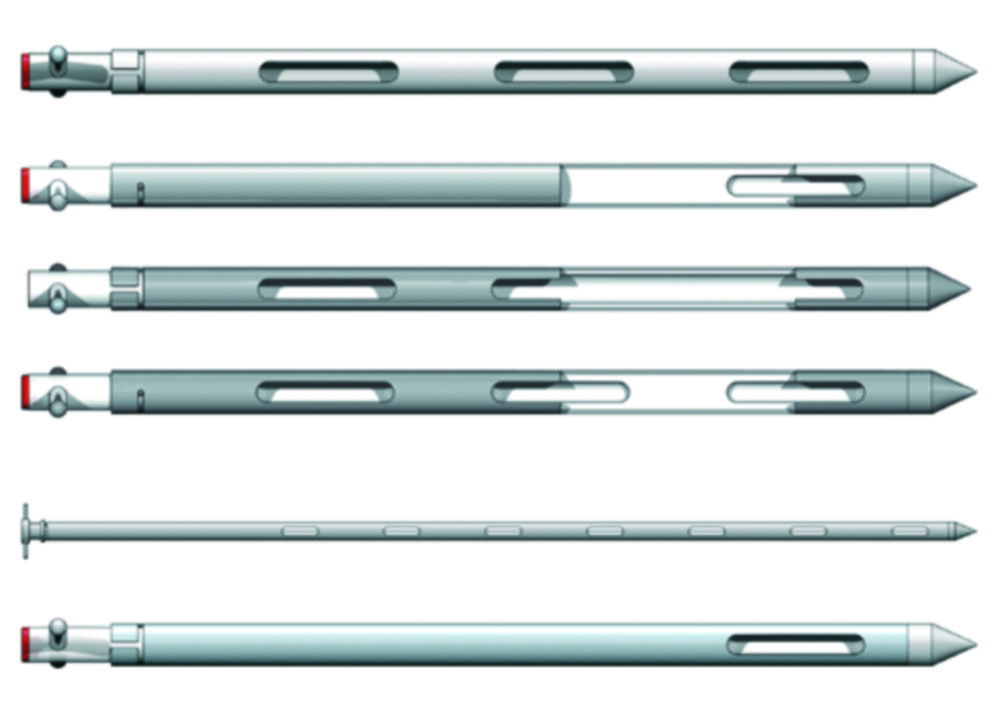

All-layer-sampler

For sampling bulk goods of all types. Easy emptying with the emptying device. Lock seal close-it and close-it food & pharma please order separately.With open inner tubes for cross-sectional sampling through all layers of the sample.

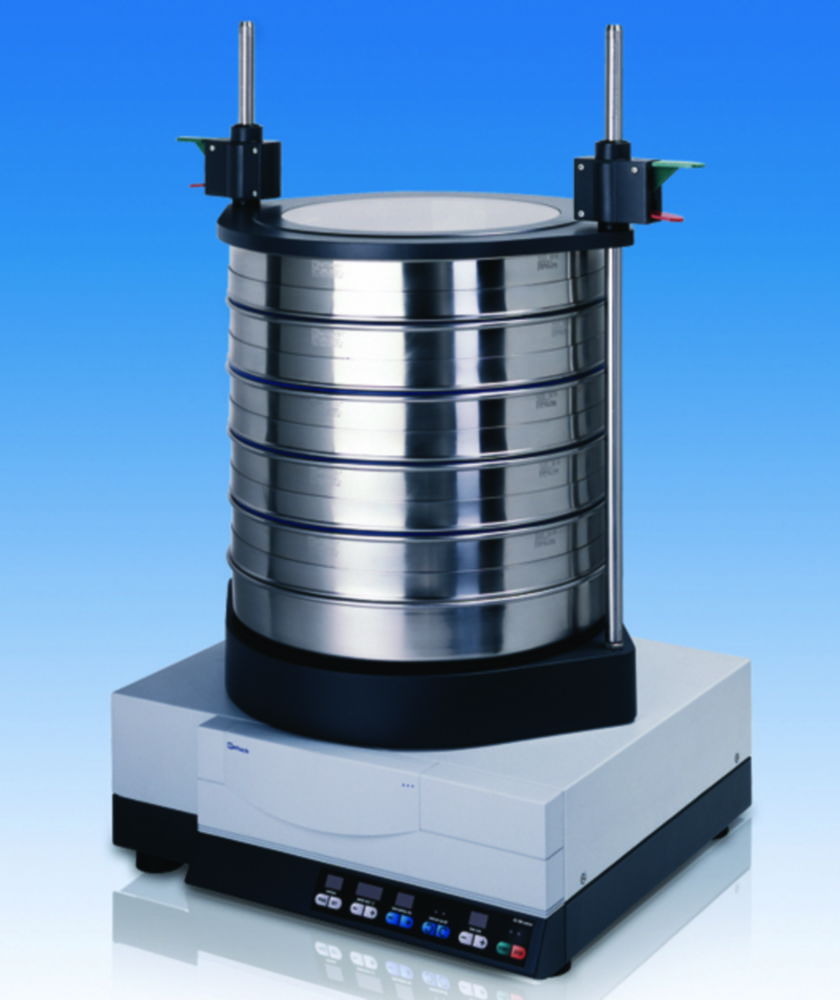

Analytical sieve shakers AS 200 basic

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Digital display of performance and timeFor dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumMaintenance-freeMax. number of fractions 9/17Please order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 200 control

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Through the integrated interface the instrument can be connected to a PC and controlled with the evaluation software EasySieve®. This program enables the user to control the whole sieving process and the subsequent documentation with convenience and accuracy.Digital adjustment of all process parameters (time, amplitude or sieve acceleration, interval)Controlled amplitudeFor dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumMaintenance-freeInterval operation, 1 ... 99 sMax. number of fractions 11/22Please order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 200 digit cA

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Digital display of vibration height and timeControlled amplitudeFor dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumMaintenance-freeInterval operation, fix 10 sMax. number of fractions 9/17Please order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 200 tap

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.For sieve analysis of certain products such as activated carbon, abrasives, metal powdee, spices and diamonds, as specified in the corresponding standards.Digital time settingSuitable for dry sievingShort sieving timesHorizontal circular sieving motion with vertical tapsMaintenance-freeMax. number of fractions 7/13Incl. software EasySieve for control through RS232 serial interfacePlease order test sieves and collecting pan separately.

Analytical sieve shakers AS 200 tap, with sound protection cabinet

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.For sieve analysis of certain products such as activated carbon, abrasives, metal powdee, spices and diamonds, as specified in the corresponding standards.Digital time settingSuitable for dry sievingShort sieving timesHorizontal circular sieving motion with vertical tapsMaintenance-freeMax. number of fractions 7/13Incl. software EasySieve for control through RS232 serial interfacePlease order test sieves and collecting pan separately.

Analytical sieve shakers AS 300 control

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Digital adjustment of all process parameters (time, amplitude or sieve acceleration, interval)For dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumLow noise, maintenance-freeInterval operation, 1 ... 99 sMax. number of fractions 11/17USB connection for use of EasySieve softwareOptional sieve software EasySieve for control of the shaker, easy evaluation and documentation of resultsPlease order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 400 control

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.The AS 400 control is used for the sieving of dry goods with test sieves of a diameter up to 400 mm. The uniform, horizontal circular motion ensures exact separation of the product to be sieved.Digital adjustment of all process parameters (time, speed, interval)Short sieving timesSieving with circular sieving motion according to DIN 53477Maintenance-freeInterval operation, 1 ... 10 minMax. number of fractions 7/9/17Memory for up to 9 SOPsIntegrated interface for evaluation software EasySieve®Please order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 450 basic

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Digital adjustment of all process parameters (time, amplitude, interval)For dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumMaintenance-freeUp to 12 fractions in one sieving operationMobile operation panel for comfortable, intuitive handlingRobust steel housingPlease order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS 450 control

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.Through the integrated interface the instrument can be connected to a PC and controlled with the evaluation software EasySieve®. This program enables the user to control the whole sieving process and the subsequent documentation with convenience and accuracy.Digital adjustment of all process parameters (time, amplitude or sieve acceleration, interval)For dry and wet sievingShort sieving timesEfficient electromagnetic driveThrowing motion with angular momentumMaintenance-freeInterval operation, 10 ... 99 sUp to 13 fractions in one sieving operationCET Technology for controlled amplitude even with high loads (up to 25 kg)Memory for up to 9 SOPsMobile operation panel for comfortable handlingOptional software EasySieve for control through RS232 serial interface, easy evaluation and documentation of resultsPlease order clamping device, test sieves and collecting pan separately.

Analytical sieve shakers AS jet

Sieve shakers are used in research and development, quality control of raw materials, interim and finished products as well as in production monitoring.For sieve cuts of powdered materials which require efficient dispersion and deagglomeration. Digital adjustment of all process parameters (time, vacuum, speed)Sieving with air jet technology for dispersion and desagglomeration of fine powdersAir jet produced by a powerful industrial vacuum cleanerVariable nozzle speedOpen mesh function to reduce the number of near-mesh particlesFree manual (standard) or automatic (accessory) pressure regulationQuick Start modeSilent operation due to integrated silencerMaintenance-freeMemory for up to 9 SOPsOptional software EasySieve for control through RS232 serial interfacePlease order test sieve and vacuum cleaner separately.