Pre-separator D360 for air jet sieve machine e200 LS eControl, dust class M + H

For active dedusting of the process air. Pre-separator system with robust steel housing. With removable 13 l collection bin and half-automatic Dust-Stop filter cleaning.Dust class type H acc. to EN 60335-2-69, separation of different dust types with all exposure limits, including carcinogenic and pathogenic dustsHEPA filter, filter class (EN 1822) H14 with a filter surface of 2.05 m2

Pre-separator D360 for air jet sieve machine e200 LS eControl, dust class M + H + ATEX

For active dedusting of the process air. Pre-separator system with robust steel housing. With removable 13 l collection bin and half-automatic Dust-Stop filter cleaning.Dust class type H acc. to EN 60335-2-69, separation of different dust types with all exposure limits, including carcinogenic and pathogenic dustsHEPA filter, filter class (EN 1822) H14 with a filter surface of 2.05 m2Antistatic, ATEX Zone 22 marking II 3 D

Pressure and temperature measuring system GrindControl for planetary ball mill PM 300

Incl. sensor, transmitter, reciever, software, case, grinding jar (incl. insert of lid), opening aid and cleaning accessories.

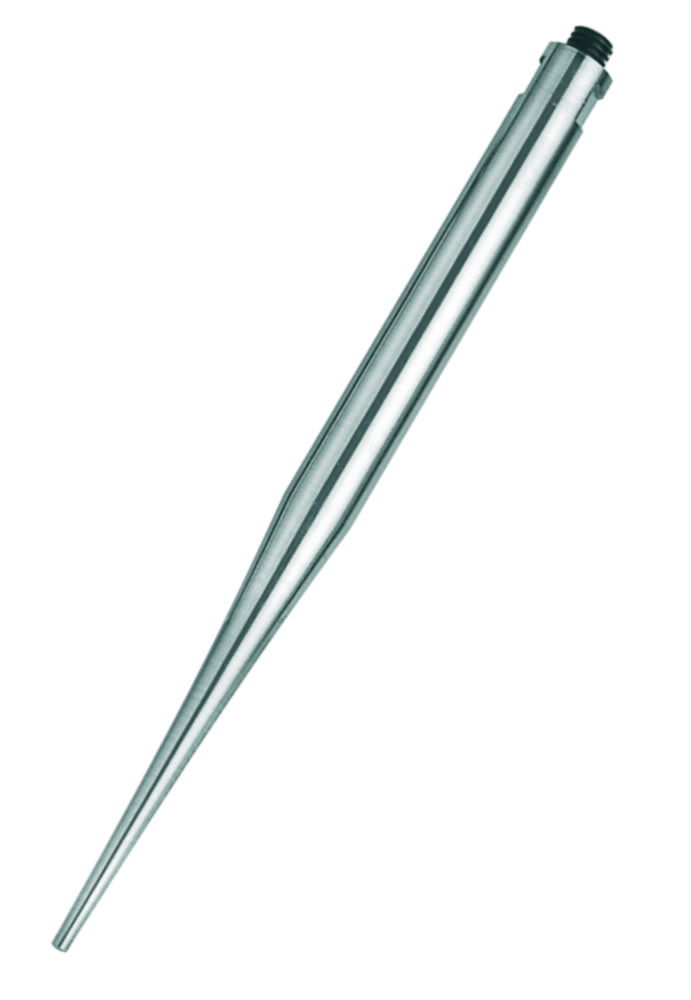

Probe extentions for Sonotrodes

For enlarging the length of the probe and to operate in deep vessels. They are mounted between standard or booster horn and titanium flat tip.

Probes for Sonopuls Ultrasonic homogenisers, microtip

Titanium probes. For connection to stepped horns/booster horns.

Probes for Sonopuls Ultrasonic homogenisers, titanium flat tip

Titanium probes. For connection to stepped horns/booster horns.

Probes for Sonopuls Ultrasonic homogenisers, titanium, long

Titanium probes. For connection to stepped horns/booster horns.

Probes for Sonopuls Ultrasonic homogenisers, titanium, tapered tip

Titanium probes. For connection to stepped horns/booster horns.

Protective covers for laboratory mixer MICROTRON®

Protective cover made of acrylic glass for use with the mixing attachments MBA 125 to MBA 1000 made of borosilicate glass.

Reusable grinding chambers for batch mill Tube Mill control/Tube Mill 100 control

Reusable grinding chambers with stainless steel beaters allow grinding up to Mohs hardness 5. Can be cleaned in the dishwasher.Scope of supply: 1 x reusable grinding cup, 25 x sealing, 5 x beater, 5 x coupling

Ring sieves, stainless steel

For Ultra Centrifugal Mill ZM 300. With reinforced rim.

Ring sieves, stainless steel, coated

For Ultra Centrifugal Mill ZM 300. With reinforced rim, wear-resistant coated.

Rotary cone sample divider LABORETTE 27

For reliable, representative sample division of solids and suspensions without conversion. Divides the samples at up to 3000 graduations per minute into up to 30 partial streams via a rotating cone head. Dividing accuracy up to 99.9 %. Can be combined with 6 different dividing heads.Compact basic unit with robust cast aluminium housingEasy cleaning due to removable dividing headvariable partition ratiosMaintenance-free drive motor with slipping clutchQuick clamping device for sample tubes 250 and 500 mlFor optimum sample allocation, the vibratory feeder LABORETTE 24 (optional) is recommended.Instrument also available in other voltages.Dividing heads must be ordered separately.

Rotary sample divider RSD200

With the optional dividing heads, the filled sample material can be divided into 6, 8 or 10 equal subsamples. The composition of each subsample corresponds exactly to the total sample. In addition, the bulk material is added and divided automatically and without loss of material.High division accuracyModular designDigital time settingSpeed monitoring and constant speed controlMaintenance-freeEasy collection and cleaningScope of supply: Rotary sample divider RSD200, vibration feeder VF200, 10 sample bottles of 250 mlPlease order rotary dividing heads separately.Number of divisions:6/8/10 (depending on dividing head)Sample bottle capacities:10/25/50/100/250/500 mlTimer:1 min ... 99 h 59 minDimensions (W x D x H):460 x 456 x 850 mmWeight:30 kgPower supply:220 V, 50/60 HzSpeed range:80 ... 120 rpm

Rotor Beater Mill SR 300

The rotor beater mill SR 300 is ideally suited for use in the laboratory and for small series production due to its robust design and the possibility to process large sample volumes. Grinding chamber, feed hopper and material inlet and outlet are completely made of high-quality stainless steel. The variable speed of up to 10000rpm allows for adaptation to specific application requirements.Features:High throughput for batchwise size reduction of large sample volumesSpeed from 3000 to 10000rpmOptional 180° grinding insert suitable for grinding hard, brittle samplesDefined final fineness due to bottom sieves with aperture sizes from 0.08 to 10mmEasy cleaning thanks to removable cassette, hopper and push fit rotorOptional distance rotor suitable for heat-sensitive samplesRing filter and collecting vessel with convenient, dust-tight bayonet catchQuick-action door lock and motor brakeFunction principle:Size reduction and deagglomeration in the SR 300 are achieved by impact and shear effects. The quick-acting door lock ensures easy access to the grinding chamber for quick cleaning. With their motor brake (braking time < 0.5s), safety switch, splashback and access barrier in the inlet and outlet areas, Rotor Beater Mills offer the highest degree of operating safety.Scope of supply: Mill with rotor, 5l collecting vessel, filter hoseBase frame, sieves and sieve frames, please order separately.