Planetary Ball Mills PM

Planetary Ball Mills are suitable for mixing and grinding soft, medium-hard, extremely hard, brittle and fibrous materials. They are used whenever high degrees of fineness down to the submicron range are to be achieved in a very short time. In addition to dry and wet grinding, they are also suitable for colloidal grinding and mechanical alloying. Typical materials are minerals, ores, chemicals, ceramics, soils, household and industrial waste etc.Features:Extremely high ultimate fineness down to submicron range1, 2 or 4 grinding stationsGrinding jar volumes from 12ml to 500mlSuitable for long-term trials and continuous useProgrammable starting timePower failure back-up ensures storage of remaining grinding timeReproducible results due to digital parameter setting10 parameter combinations can be storedSingle button operation with graphic displayAutomatic grinding chamber ventilation for cooling the grinding jarsGrinding jars in 7 sizes and 8 different materials availableSupplied with: Planetary Ball Mill only. Grinding jars and grinding balls have to be ordered separately.Please order grinding jars and grinding balls separately.

Planetary ball mills PULVERISETTE 5 classic line

Ideal for fast, loss-free fine grinding of hard, medium-hard, brittle and fibrous materials - dry or in suspension in the areas of geology, mineralogy, metallurgy, ceramics, materials research, mechanical alloying, pharmaceuticals, chemistry, biology, sample preparation for analysis.Sample can be processed from a few mg to several kg at a wide range of fineness levels down to less than 1 µm. They are especially easy to operate and fast and easy to clean. Suitable for continuous, heavy duty usage and guarantee safe clamping of the grinding bowls.Matching grinding parts of 7 different materials are available to provide max.protection against undesired contamination. In addition to size-reduction, planetary ball mills can also be used for mixing and homogenising of emulsions and pastes or for mechanical alloying and activation.FRITSCH also offers a Planetary Mill Generation premium line, for fast high-tech grinding down to the nano range, worldwide unique in operation, performance and safety, a new reference class. Information on the Planetary Mill PULVERISETTE 5 premium line and Planetary Micro Mill PULVERISETTE 7 premium line can be found in the LLG Online Shop.Grinding bowls and grinding balls must be ordered additionally.Further models of planetary mills on request.

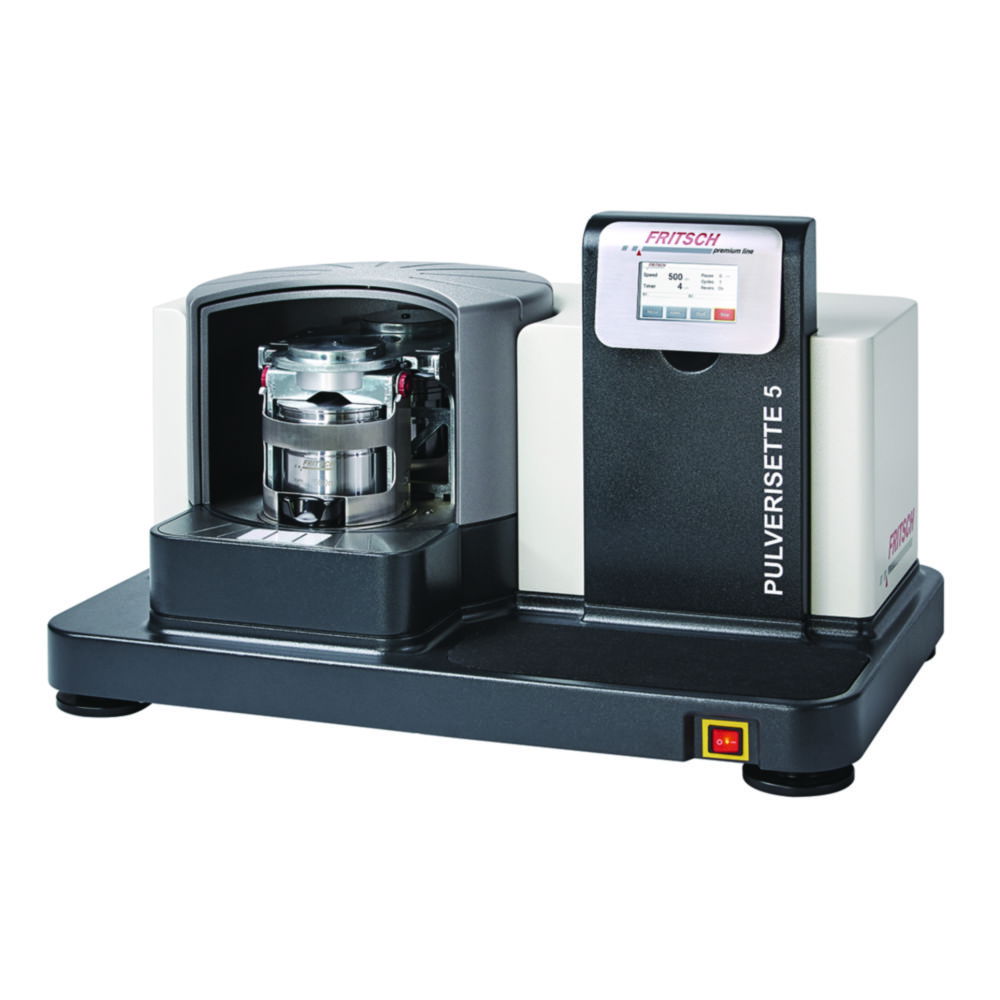

Planetary ball mills PULVERISETTE 5 premium line

Ideal for high-performance grinding down into the nano range of hard, medium-hard, brittle and fibrous materials with extremely short grinding times dry, in suspension or in inert gas in the areas of nanotechnology, geology, mineralogy, metallurgy, ceramics, materials research, mechanical alloying/activation, pharmaceuticals, chemistry, biology, sample preparation for analysis. They are also the perfect choice for highly efficient mixing and homogenizing.Grinding bowls and balls are offered in different sizes for optimal adaption to the sample volume and desired final fineness as well as in different materials to provide maximum protection against undesired contamination.The completely brand new clamping of the grinding bowls, the automatic check of the fastening of the bowls inside the mill, the blockage of the mill in the event of impermissible operating states or imbalance and the automatic bowl detection guarantee maximum safety.Grinding bowls and grinding balls must be ordered additionally.Software MillControl for automatic control of the Planetary mills PULVERISETTE 5/7 premium line.

Planetary ball mills PULVERISETTE 7 premium line

Ideal for high-performance grinding down into the nano range of hard, medium-hard, brittle and fibrous materials with extremely short grinding times dry, in suspension or in inert gas in the areas of nanotechnology, geology, mineralogy, metallurgy, ceramics, materials research, mechanical alloying/activation, pharmaceuticals, chemistry, biology, sample preparation for analysis. They are also the perfect choice for highly efficient mixing and homogenizing.Grinding bowls and balls are offered in different sizes for optimal adaption to the sample volume and desired final fineness as well as in different materials to provide maximum protection against undesired contamination.The completely brand new clamping of the grinding bowls, the automatic check of the fastening of the bowls inside the mill, the blockage of the mill in the event of impermissible operating states or imbalance and the automatic bowl detection guarantee maximum safety.Grinding bowls and grinding balls must be ordered additionally.Software MillControl for automatic control of the Planetary mills PULVERISETTE 5/7 premium line.

Planetary mono mills PULVERISETTE 6 classic line

Ideal for fast, loss-free fine grinding of hard, medium-hard, brittle and moist materials - dry, in suspension, or under inert gas in the areas of geology, mineralogy, metallurgy, ceramics, pharmaceuticals, chemistry, biology, sample preparation for analysis.Sample can be processed from a few mg to several kg at a wide range of fineness levels down to less than 1 µm. They are especially easy to operate and fast and easy to clean. Suitable for continuous, heavy duty usage and guarantee safe clamping of the grinding bowls.Matching grinding parts of different materials are available to provide max.protection against undesired contamination. In addition to size-reduction, planetary ball mills can also be used for mixing and homogenising of emulsions and pastes or for mechanical alloying and activation.Grinding bowls and grinding balls must be ordered additionally.

Pressure and temperature measuring system GrindControl for planetary ball mill PM 300

Incl. sensor, transmitter, reciever, software, case, grinding jar (incl. insert of lid), opening aid and cleaning accessories.

Reusable grinding chambers for batch mill Tube Mill control/Tube Mill 100 control

Reusable grinding chambers with stainless steel beaters allow grinding up to Mohs hardness 5. Can be cleaned in the dishwasher.Scope of supply: 1 x reusable grinding cup, 25 x sealing, 5 x beater, 5 x coupling

Ring sieves, stainless steel

For Ultra Centrifugal Mill ZM 300. With reinforced rim.

Ring sieves, stainless steel, coated

For Ultra Centrifugal Mill ZM 300. With reinforced rim, wear-resistant coated.

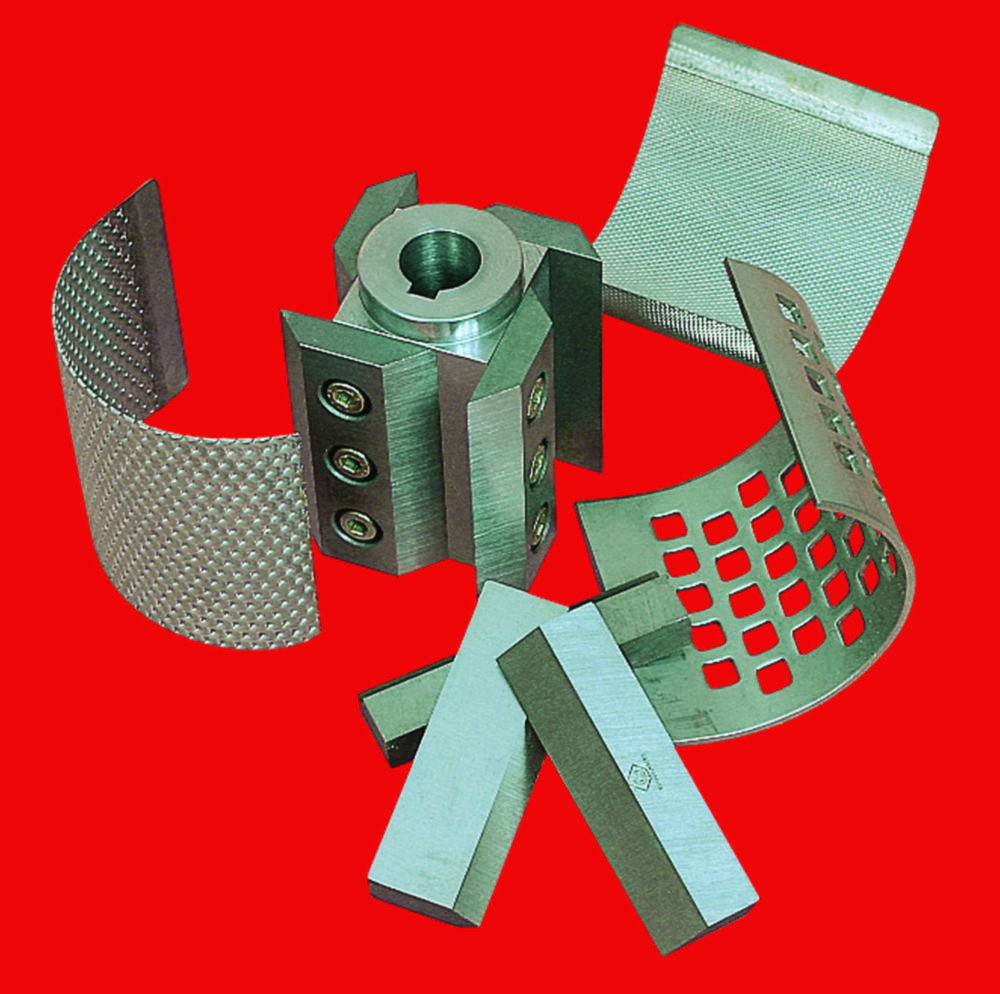

Rotor Beater Mill SR 300

The rotor beater mill SR 300 is ideally suited for use in the laboratory and for small series production due to its robust design and the possibility to process large sample volumes. Grinding chamber, feed hopper and material inlet and outlet are completely made of high-quality stainless steel. The variable speed of up to 10000rpm allows for adaptation to specific application requirements.Features:High throughput for batchwise size reduction of large sample volumesSpeed from 3000 to 10000rpmOptional 180° grinding insert suitable for grinding hard, brittle samplesDefined final fineness due to bottom sieves with aperture sizes from 0.08 to 10mmEasy cleaning thanks to removable cassette, hopper and push fit rotorOptional distance rotor suitable for heat-sensitive samplesRing filter and collecting vessel with convenient, dust-tight bayonet catchQuick-action door lock and motor brakeFunction principle:Size reduction and deagglomeration in the SR 300 are achieved by impact and shear effects. The quick-acting door lock ensures easy access to the grinding chamber for quick cleaning. With their motor brake (braking time < 0.5s), safety switch, splashback and access barrier in the inlet and outlet areas, Rotor Beater Mills offer the highest degree of operating safety.Scope of supply: Mill with rotor, 5l collecting vessel, filter hoseBase frame, sieves and sieve frames, please order separately.

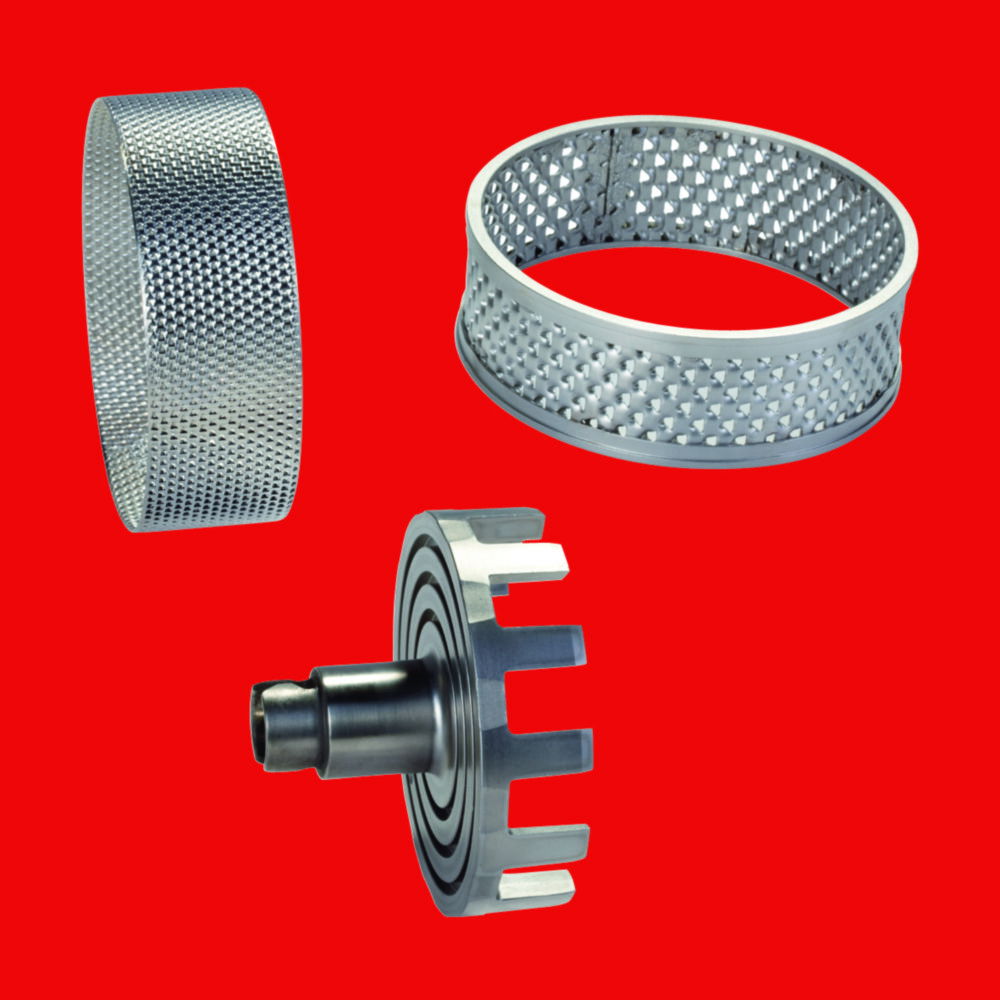

Rotors for Ultra Centrifugal Mill

Further Ring sieves and rotors available on request.

Spare parts set for reusable grinding chambers

Scope of supply: 100 x sealing, 10 x beater, 10 x coupling