Accessories for vacuum ovens VO

Premium module: The premium module comprises the inert gas inlet (only sizes 49/101), extra connectors for thermoshelves, one for VO29, two for VO49/VO101, an additional thermoshelf for model size 49/101.Vacuum pump module: Without pump with antivibration metal plate at the bottom to accommodate the vacuum pump, including full-sight glass door, socket, signal cable and connecting hose to the vacuum oven.Chemical-resistant vacuum pump: With 4x diaphragm, pump capacity: approx. 50 Nl/min = 3.0 m/h³, automatic purge control, with signal cable (3 m) to control the rotation speed and vacuum connecting hose (3 m).

ATEX Chemical membrane pump VP5 EX

The VP5 EX vacuum pump, together with the VDL series vacuum drying ovens, is ideally suited for the safe drying of flammable solvents.Resistant to a wide range of chemicalsVery quiet and low-vibration operationDesigned for S1 operating mode (continuous operation)Suction and pressure-side separators for collecting condensateEmission condenser at the pump outlet for solvent recondensationPower connection via fixed connection, pump supplied with blank cable ends without plugATEX-compliant

Chemical membrane pump VP1

The VP1 vacuum pump, together with the VD series vacuum drying ovens, is ideally suited for drying aqueous and non-flammable solvents.Resistant to a wide range of chemicalsVery quiet and low-vibration operationDesigned for S1 operating mode (continuous operation)Suction and pressure-side separators for collecting condensate

Chemical membrane pump VP2

The VP2 vacuum pump, together with the VD series vacuum drying ovens, is ideally suited for drying aqueous and non-flammable solvents.Resistant to a wide range of chemicalsVery quiet and low-vibration operationDesigned for S1 operating mode (continuous operation)Suction and pressure-side separators for collecting condensate

Compact vacuum oven Vacutherm™ VT 6025

For the gentle and rapid drying or heat treatment of temperature sensitive substances and components in the electronics, pharmacy, cosmetics and biochemistry fields. With double glazed safety glass door window, very low external casing temperature, freely adjustable overheat cut-out with separate temperature sensor, Kelvitron® microprocessor controlled temperature controller and pull-out, non-tilting shelves with end stops.For the gentle and rapid drying or heat treatment of temperature sensitive substances and components in the electronics, pharmacy, cosmetics and biochemistry fields. With double glazed safety glass door window, very low external casing temperature, freely adjustable overheat cut-out with separate temperature sensor, Kelvitron® microprocessor controlled temperature controller and pull-out, non-tilting shelves with end stops.

Compact vacuum oven Vacutherm™ VT 6025, with inert gas connection

For the gentle and rapid drying or heat treatment of temperature sensitive substances and components in the electronics, pharmacy, cosmetics and biochemistry fields. With double glazed safety glass door window, very low external casing temperature, freely adjustable overheat cut-out with separate temperature sensor, Kelvitron® microprocessor controlled temperature controller and pull-out, non-tilting shelves with end stops.With stainless steel vacuum ball valve, inert gas connection, overpressure safety and precision valve, seamlessly welded chamber, and DN25 access port

Compact vacuum oven Vacutherm™ VT 6025, with inert gas connection, digital pressure display, and recorder connection

For the gentle and rapid drying or heat treatment of temperature sensitive substances and components in the electronics, pharmacy, cosmetics and biochemistry fields. With double glazed safety glass door window, very low external casing temperature, freely adjustable overheat cut-out with separate temperature sensor, Kelvitron® microprocessor controlled temperature controller and pull-out, non-tilting shelves with end stops.With stainless steel vacuum ball valve, inert gas connection, digital pressure display, recorder connection, overpressure safety and precision valve, seamlessly welded chamber, and DN25 access port

Diaphragm Pumps for Vacuum Ovens

Gentle drying of heat sensitive materialsSignificantly reduced drying times when compared to convectional oven without vacuumDrying of intricately designed partsElimination of oxidation associated with heat treatmentTargeted recovery of degassed productCapacity refers to the trap in ml* Rotary Vane Pump, Water Vapor Compatibility 40 mbar.

Diaphragm Pumps for Vacuum Ovens

Gentle drying of heat sensitive materialsSignificantly reduced drying times when compared to convectional oven without vacuumDrying of intricately designed partsElimination of oxidation associated with heat treatmentTargeted recovery of degassed productCapacity refers to the trap in ml* Rotary Vane Pump, Water Vapor Compatibility 40 mbar.

LLG-Evaporating dishes with flat bottom, porcelain, medium form

Ideal for evaporating liquids or solvents. Glazed on the inside and outside.With spoutTemperature resistant up to 900 °C

Pump cabinet set VD with vacuum pump VP1

Set consisting of VP1 vacuum pump, pump cabinet (under cabinet) for housing the pump and a connection kit for connecting the pump to the VD series vacuum drying oven. The under cabinet raises the vacuum drying chamber to an ergonomic working height, reduces pump noise and protects the pump from mechanical damage. The pump cabinet contains a switchable socket that can be controlled via the controller of the vacuum drying oven.

Pump cabinet set VD with vacuum pump VP2

Set consisting of VP2 vacuum pump, pump cabinet (under cabinet) for housing the pump and a connection kit for connecting the pump to the VD series vacuum drying oven. The under cabinet raises the vacuum drying chamber to an ergonomic working height, reduces pump noise and protects the pump from mechanical damage. The pump cabinet contains a switchable socket that can be controlled via the controller of the vacuum drying oven.

Pump cabinet set VDL with vacuum pump VP5 EX

Set consisting of VP5 EX vacuum pump, pump cabinet (under cabinet) for housing the pump and a connection kit for connecting the pump to the VDL series vacuum drying oven. The under cabinet raises the vacuum drying chamber to an ergonomic working height, reduces pump noise and protects the pump from mechanical damage. The pump cabinet contains a stainless steel drip tray. There is an exhaust port (Ø 100 mm) on the rear wall of the pump cabinet for connection to an on-site exhaust system.

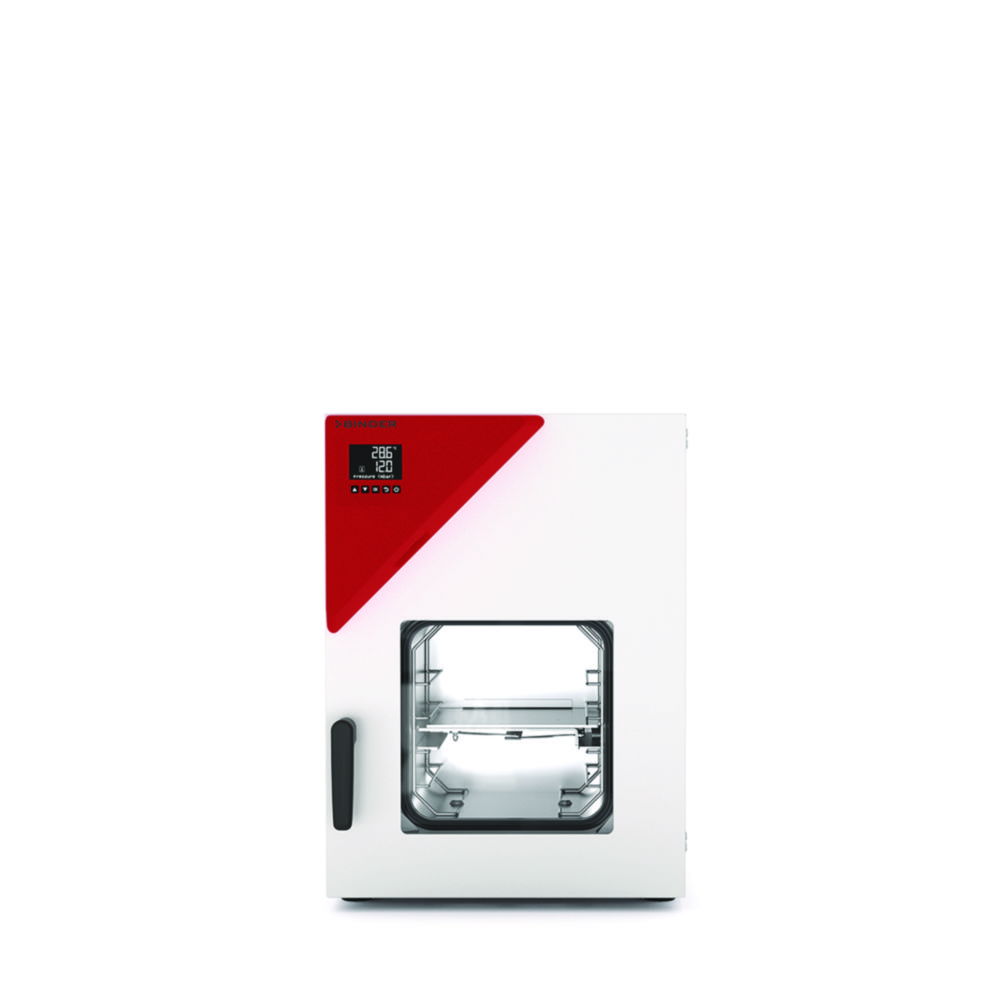

Vacuum drying ovens VD series

For gentle, fast drying without residues, incrustations or oxidation.Direct heat transfer through large thermal conducting platesProgram-controlled drying monitoring with automatic ventilation at end of processInternal data logger, measured values can be read out in open format via USBInert gas connectionShatterproof, spring-mounted safety glass panelLarge viewing windowAluminum expansion racks, can be custom-positionedEthernet interfaceFor non-flammable solventsController with digital display of pressure and temperatureAccess port DN 16

Vacuum drying ovens VDL series

For gentle, fast drying without residues, incrustations or oxidation.Direct heat transfer through large thermal conducting platesProgram-controlled drying monitoring with automatic ventilation at end of processInternal data logger, measured values can be read out in open format via USBInert gas connectionShatterproof, spring-mounted safety glass panelLarge viewing windowAluminum expansion racks, can be custom-positionedEthernet interfaceFor flammable solventsATEX conformity for units: EX II 2/3/- G IIB T3 Gb/Gc/- XIntuitive touchscreen controller with graphical pressure and temperature displayPressure control device for heating activated from <100 mbar

Vacuum oven Vacutherm™ VT 6000 M, heated jacket

For the careful, rapid drying and heat treatment of temperature sensitive substances and components in the electronics, pharmaceutical, cosmetic and biochemical industries. Also features analogue pressure display, stainless steel ball valve to control vacuum, rapid air ventilation valve, inert gas connection with pressure relief safety valve for controlled chamber purging and corrosion resistant vacuum fittings.With electro-polished and internally welded, rectangular chamber made of 1.4571 stainless steelSilicone door sealSmall flange (DN 25 KF) vacuum fittings are positioned on the rear panel of the cabinetAn overheat cut-out (Class 2) is supplied as standardHeat is conducted from the heated chamber through the shelves to the sample. The shelves are removeable. With Kelvitron® microprocessor temperature controller.Fully equipped vacuum pump control station Vacucenter available as an accessory for Vacutherm™ 6060 and 6130 ovens. Choice of 3 different vacuum pumps available according to operating conditions.

Vacuum oven Vacutherm™ VT 6000 M-BL, heated jacket, for flammable solvents

For the careful, rapid drying and heat treatment of temperature sensitive substances and components in the electronics, pharmaceutical, cosmetic and biochemical industries. Also features analogue pressure display, stainless steel ball valve to control vacuum, rapid air ventilation valve, inert gas connection with pressure relief safety valve for controlled chamber purging and corrosion resistant vacuum fittings.With electro-polished and internally welded, rectangular chamber made of 1.4571 stainless steelSilicone door sealSmall flange (DN 25 KF) vacuum fittings are positioned on the rear panel of the cabinetAn overheat cut-out (Class 2) is supplied as standardHeat is conducted from the heated chamber through the shelves to the sample. The shelves are removeable. With Kelvitron® microprocessor temperature controller.