Protective cover for rotary evaporator RE 212 FW-G

Protective cover for the heating bath of the rotary evaporator RE 212 FW-G.

Receiving flasks, DURAN®

Especially for rotary evaporators, with spherical joint socket S 35, autoclavable, material: DURAN®.

Receiving flasks, DURAN®, with PUR coating

Especially for rotary evaporators, with spherical joint socket S 35, autoclavable, material: DURAN®.

Receiving flasks, with spherical ground glass joint, borosilicate glass 3.3

Receiving flasks with spherical ground glass joint KS35 suitable for all Rotary evaporators.

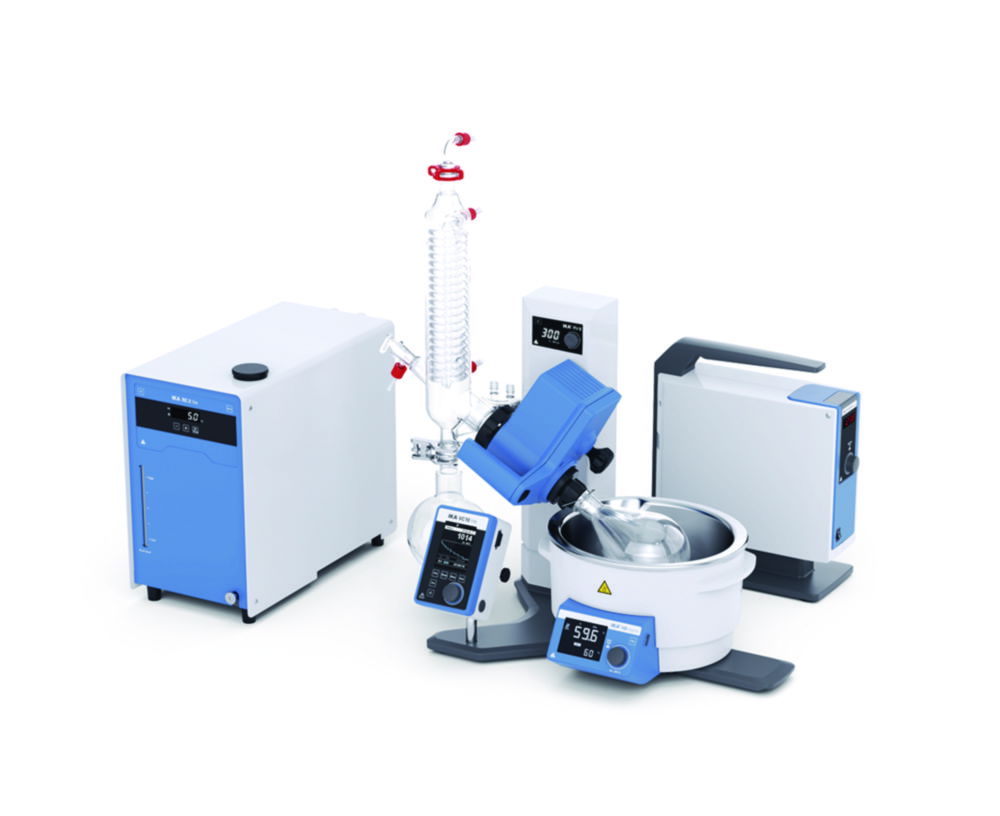

Rotary evaporator package RV 10 auto pro V-C Complete

The complete solution for a rotary evaporator setup. In addition to the RV 10 auto rotary evaporator, the package includes the HB digital heating bath, the VACSTAR digital vacuum pump and the RC 2 lite circulation cooler.Rotary evaporator RV 10 auto with intuitive TFT colour display and integrated vacuum controller with automatic control of the vacuum and cooling water monitoringVacuum pump VACSTAR digital achieves a minimum vacuum of 2 mbar, is controlled directly by the RV 10 auto drive unit via the data cable suppliedCirculating cooler RC 2 lite with 400 W cooling capacity and pressure and suction pump with 0.35 bar for simple cooling tasks down to -10 °CScope of supply: RV10 control rotary evaporator, RV 10.10 glassware, RV 10.70 vapour feed-through tube, HB digital S099 heating bath, VACSTAR digital vacuum pump, H.SI.8 vacuum hose, VSE 1 condenser, RC 2 lite circulation cooler, H 11 mains cable

Rotary evaporator package RV 10 auto Starter Solution

The Starter Solution is the complete package for the rotary evaporator setup. The RV 10 auto offers features such as smooth start, left-right interval and timer function. It impresses with its intuitive operation via a TFT colour graphic display, an integrated vacuum controller, cooling water monitoring and safety standards. The motorised lift has an automated lift-out function in case of power outage to prevent superheating of the solvent. The USB or RS232 interface allows remote control using the IKA software labworldsoft® and the option of updating using the Firmware Update Tool.Scope of supply: rotary evaporator RV 10 auto, VACSTAR lite vacuum pump, HB digital heating bath, vertical glass condenser set with 1 l receiver and evaporator flask, RC 2 lite recirculating chiller, hoses, cable

Rotary evaporator package RV 10 digital pro V Complete

Complete solution for a rotary evaporator setup with the robust and reliable companion for all distillation tasks including heating bath HB digital and vertical glassware. This rotary evaporator is characterised by innovative features and remote control of the various components as well as increased safety through motor-driven lift, safety temperature circuit and dry-running protection.With extremely space-saving vacuum pump VACSTAR digital, which achieves a minimum vacuum of 2 mbar.The vacuum controller VC 10 lite is used for control. In addition to controlling the recirculating cooler RC 2 lite, it enables manual setpoint input of the vacuum as well as programme-controlled operation.The powerful compact RC 2 lite recirculating cooler with 400 W cooling capacity and a strong pressure and suction pump (0.35 bar) is designed for simple cooling tasks down to -10 °C.Scope of supply: Rotary evaporator, vacuum pump VACSTAR digital, vacuum controller VC 10 lite, recirculating cooler RC 2 lite, table stand VC 10.400, hose set RV 10.5005, data cable PC 1.3

Rotary evaporator package RV 10 digital pro V double Complete

Complete solution for a rotary evaporator setup with two rotary evaporators including two HB digital heating baths and two vertical glassware sets are the robust and reliable companions for all distillation tasks. They are characterised by innovative features and remote control of the various components as well as increased safety due to motor-driven lift, safety temperature circuit and dry-running protection.With extremely space-saving vacuum pump VACSTAR digital plus vacuum safety emmision condenser VSE 1. A minimum vacuum of 2 mbar can be achieved. One vacuum source is sufficient to supply both rotary evaporators.Controlling is done via the two included vacuum controllers VC 10 pro.The powerful and energy-efficient RC 2 GREEN basic recirculating chiller is suitable for cooling tasks down to -30 °C. The demand- and speed-controlled compressor achieves a cooling capacity of 800 W.Scope of supply: 2 x Rotary evaporator, vacuum pump VACSTAR digital + vacuum safety emmision condenser VSE 1, 2 x vacuum controller VC 10 pro, recirculating cooler RC 2 GREEN basic, 2 x table stand VC 10.400, 2 x hose set RV 10.5005, 2 x non-return valves VC 10.300, data cable PC 1.3, 2 x Y-distributor

Rotary evaporator package RV 10 digital Starter Solution

The Starter Solution is the complete package for the rotary evaporator setup. The RV 10 digital offers features such as smooth start, left-right interval and timer function. The motorized lift has an automated lift-out function in case of power outage to prevent superheating of the solvent. The RS 232 interface allows for remote control via the software labworldsoft®. The heating bath is controlled from the main unit via the IR interface.Scope of supply: rotary evaporator RV 10 digital Flex, VACSTAR lite vacuum pump, VC 10 lite vacuum controller, HB digital heating bath, vertical glass condenser set with 1 l receiver and evaporator flask, RC 2 lite recirculating chiller, stand pole, set of hoses, cable

Rotary evaporator package RV 3 pro V Complete

Complete solution for a rotary evaporator setup with the ideal entry-level model including heating bath HB eco and vertical glassware.With extremely space-saving vacuum pump VACSTAR digital, which achieves a minimum vacuum of 2 mbar.The vacuum controller VC 10 lite is used for control. In addition to controlling the recirculating cooler RC 2 lite, it enables manual setpoint input of the vacuum as well as programme-controlled operation.The powerful compact RC 2 lite recirculating cooler with 400 W cooling capacity and a strong pressure and suction pump (0.35 bar) is designed for simple cooling tasks down to -10 °C.Scope of supply: Rotary evaporator, vacuum pump VACSTAR digital, vacuum controller VC 10 lite, recirculating cooler RC 2 lite, stand pole VC 10.500, hose set RV 10.5005, data cable PC 1.3

Rotary evaporator package RV 3 Starter Solution

The Starter Solution is the complete package for the rotary evaporator setup. The RV 3 rotary evaporator is the ideal entry-level model. It finds a multitude of uses in the chemical, pharmaceutical and biotechnology industries, in research and development, in manufacturing and quality assurance, in laboratories and in plant construction.Scope of supply: rotary evaporator RV 3 Flex, VACSTAR lite vacuum pump, VC 10 lite vacuum controller, HB eco heating bath, vertical glass condenser set with 1 l receiver and evaporator flask, RC 2 lite recirculating chiller, stand pole, set of hoses, cable

Rotary evaporator package RV 8 pro V Complete

Complete solution for a rotary evaporator setup with the manual base unit including heating bath HB digital and vertical glassware. Digital displays for rotation speed and heating bath temperature allow optimal control of all distillation processes.With extremely space-saving vacuum pump VACSTAR digital, which achieves a minimum vacuum of 2 mbar.The vacuum controller VC 10 lite is used for control. In addition to controlling the recirculating cooler RC 2 lite, it enables manual setpoint input of the vacuum as well as programme-controlled operation.The powerful compact RC 2 lite recirculating cooler with 400 W cooling capacity and a strong pressure and suction pump (0.35 bar) is designed for simple cooling tasks down to -10 °C.Scope of supply: Rotary evaporator, vacuum pump VACSTAR digital, vacuum controller VC 10 lite, recirculating cooler RC 2 lite, stand pole RV 8.3, hose set RV 10.5005, data cable PC 1.3

Rotary evaporator package RV 8 Starter Solution

The Starter Solution is the complete package for the rotary evaporator setup. The RV 8 is a manual basic model. It finds a multitude of uses in the chemical, pharmaceutical, and biotechnology industries, in research and development, in manufacturing and quality assurance, in laboratories, and in plant construction. Digital displays for speed and heating bath temperature enable optimum control of all distillation processes.Scope of supply: rotary evaporator RV 8 Flex, VACSTAR lite vacuum pump, VC 10 lite vacuum controller, HB digital heating bath, vertical glass condenser set with 1 l receiver and evaporator flask, RC 2 lite recirculating chiller, stand pole, set of hoses, cable

Rotary evaporator RE 212 FW-G

Rotary evaporator with user-friendly interface and manual height adjustment for simple and safe operation. The compact design makes optimum use of the available laboratory space. For applications such as powder drying and suspensions, the evaporator flask can be rotated clockwise or counterclockwise.Coated glasswareIntuitive control unit with digital displayRobust and chemical-resistant vacuum sealCompact heating bath with digital displayHeating bath can be positioned on the right or leftSmall footprintProtective cover for heating bath optionally available. Please order separately.

Rotary evaporator RE-100D with motor lift

The rotary evaporator RE-100D is suitable for all distillation tasks. The motorized lift is equipped with a safety function that automatically lifts the flask out of the heating bath in case of power failure. LCD display shows temperature, speed and time.Final position recognitionPush-off mechanismTimer functionInterval operation left/rightUSB interfaceVertical condenser. Coated condenser as optionScope of supply: Rotary evaporator, vertical condenser

Rotary evaporator Rotavapor® R-300 System with Interface I-300 and heating bath B-301

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300: with VacuBox, Woulff bottle. Operation by navigation knob and function keys. Wide range of operating modes (manual, timer, solvent library, automatic distillation, drying). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring.Heating bath B-301: Temperature range of up to 95 °C (water). Max. evaporating flasks size: 1000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature. Fast heat up time.

Rotary evaporator Rotavapor® R-300 System with Interface I-300 Pro and heating bath B-301

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300 pro: With VacuBox, Woulff bottle. Operation by touch screen or navigation knob. Wide range of operating modes (methods, manual, timer, solvent library, automatic distillation, drying). Charting and recording possibilities (on SD card). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring (including charting).Heating bath B-301: Temperature range of up to 95 °C (water). Max. evaporating flasks size: 1000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature. Fast heat up time.

Rotary evaporator Rotavapor® R-300 System with Interface I-300 Pro, heating bath B-301 and recirculating chiller F-305

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300 Pro: with VacuBox, Woulff bottle. Operation by touch screen or navigation knob. Wide range of operating modes (methods, manual, timer, solvent library, automatic distillation, drying). Charting and recording possibilities (on SD card). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring (including charting).Heating Bath B-301: Temperature range up to 95 °C (water). Max. evaporating flasks size: 1000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature. Fast heat up time.Recirculating chiller F-305: Ecological recirculating chiller. Cooling capacity: 550 W at 15 °C. Temperature range: - 10 °C to 25 °C. Rotation knob for set temperature in steps of 0.1 °C. Lock of cooling temperature. In combination with Interfaces I-300 / I-300 Pro: Temperature setting/monitoring via interface, energy-saving eco-mode and automatic ON/OFF.

Rotary evaporator Rotavapor® R-300 system, with Interface I-300 and heating bath B-305

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300: with VacuBox, Woulff bottle. Operation by navigation knob and function keys. Wide range of operating modes (manual, timer, solvent library, automatic distillation, drying). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring.Heating bath B-305: Temperature range up to 220 °C. Max. evaporating flasks size: 5000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature.

Rotary evaporator Rotavapor® R-300 system, with Interface I-300 pro and heating bath B-305

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300 pro: With VacuBox, Woulff bottle. Operation by touch screen or navigation knob. Wide range of operating modes (methods, manual, timer, solvent library, automatic distillation, drying). Charting and recording possibilities (on SD card). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring (including charting).Heating bath B-305: Temperature range up to 220 °C. Max. evaporating flasks size: 5000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature.

Rotary evaporator Rotavapor® R-300 system, with Interface I-300 pro, heating bath B-305 and recirculating chiller F-305

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300 pro: with VacuBox, Woulff bottle. Operation by touch screen or navigation knob. Wide range of operating modes (methods, manual, timer, solvent library, automatic distillation, drying). Charting and recording possibilities (on SD card). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring (including charting).Heating bath B-305: Temperature range up to 220 °C. Max. evaporating flasks size: 5000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature.Recirculating chiller F-305: Ecological recirculating chiller. Cooling capacity: 550 W at 15 °C. Temperature range: - 10 °C to 25 °C. Rotation knob for set temperature in steps of 0.1 °C. Lock of cooling temperature. In combination with Interfaces I-300 / I-300 Pro: Temperature setting/monitoring via interface, energy-saving eco-mode and automatic ON/OFF.

Rotary evaporator Rotavapor® R-300 system, with Interface I-300, heating bath B-301 and recirculating chiller F-305

Its modular design allows the R-300 to be extended to a fully integrated system. All components can be regulated via a central interface. Every rotary evaporator Rotavapor® R-300 will be delivered with a transparent PLASTIC+GLAS (P+G) safety coating, a vertical glass assembly (V), NS29/32, and a vacuum pump V-300.Vacuum pump V-300: (1.8 m3/h, 5 mbar) is a chemically resistant PTFE diaphragm vacuum pump with transparent front panel to observe the membrane for highest distillation efficiency. Final vacuum: 5 mbar (±2 mbar). Suction capacity: 1.8 m3/h. Speed-controlled operation.Interface I-300: with VacuBox, Woulff bottle. Operation by navigation knob and function keys. Wide range of operating modes (manual, timer, solvent library, automatic distillation, drying). Compatible with BUCHI Rotavapor App for mobile push notifications and remote monitoring.Heating bath B-301: Temperature range up to 95 °C (water). Max. evaporating flasks size: 1000 mL (3 kg). Cordless connection. Digital display of set and actual temperature, rotation speed, lift position. Lock of heating temperature. Fast heat up time.Recirculating chiller F-305: Ecological recirculating chiller. Cooling capacity: 550 W at 15 °C. Temperature range: - 10 °C to 25 °C. Rotation knob for set temperature in steps of 0.1 °C. Lock of cooling temperature. In combination with Interfaces I-300 / I-300 Pro: Temperature setting/monitoring via interface, energy-saving eco-mode and automatic ON/OFF.