Flat flange lids, PTFE, DN 100, Typ 2

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)2 x NPT 1/2" female thread (directly to the center)1 x NPT 1/2" female thread (aside to the center)1 x NPT 3/4" female thread (aside to the center)1 x NPT 1/4" female thread (vertical)

Flat flange lids, PTFE, DN 100, Typ 3

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)2 x NPT 1/2" female thread (directly to the center)1 x NPT 1/2" female thread (aside to the center)1 x NPT 1/4" female thread (aside to the center)1 x NPT 1/4" female thread (vertical)

Flat flange lids, PTFE, DN 150, Typ 1

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)2 x NPT 1/2" female thread (directly to the center)1 x NPT 1/2" female thread (aside to the center)1 x NPT 1/4" female thread (aside to the center)1 x NPT 1/4" female thread (vertical)

Flat flange lids, PTFE, DN 150, Typ 2

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)2 x NPT 1/2" female thread (directly to the center)1 x NPT 1/2" female thread (aside to the center)1 x NPT 3/4" female thread (aside to the center)1 x NPT 1/4" female thread (vertical)

Flat flange lids, PTFE, DN 150, Typ 3

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)1 x NPT 1/2" female thread (directly to the center)1 x NPT 1" female thread (directly to the center)1 x NPT 1/2" female thread (aside to the center)1 x NPT 1/4" female thread (aside to the center)1 x NPT 1/4" female thread (vertical)

Flat flange lids, PTFE, DN 60, Typ 1

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)1 x NPT 1/4" female thread (directly to the center)2 x NPT 1/2" female thread (aside to the center)

Flat flange lids, PTFE, DN 60, Typ 2

The flat flange allows the lid to be securely attached to the reactor body and ensures a reliable seal to prevent leakage. Compatible according to DIN 12214.1 x NPT 1/2" female thread (centered)3 x NPT 1/2" female thread (aside to the center)

Flat ground flange lids, DURAN®

With four ground joint necks as outlined below. 1 bar max. operating pressure at 250 °C. Glass Type I / neutral glass as per USP, EP and JP. Autoclavable.

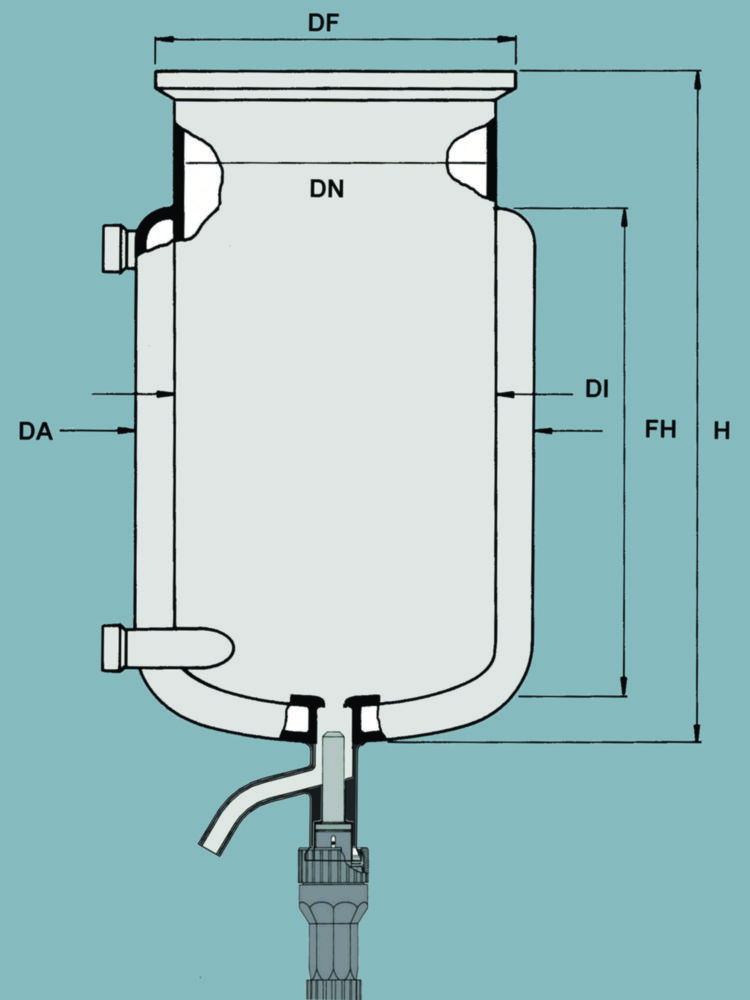

Flat ground flange reaction vessels, jacketed

Flange with groove in accordance with DIN 12214. Flask with thermostatic jacket and type "T" 10mm bore PTFE drain valve.Further accessories and spare parts available on request.

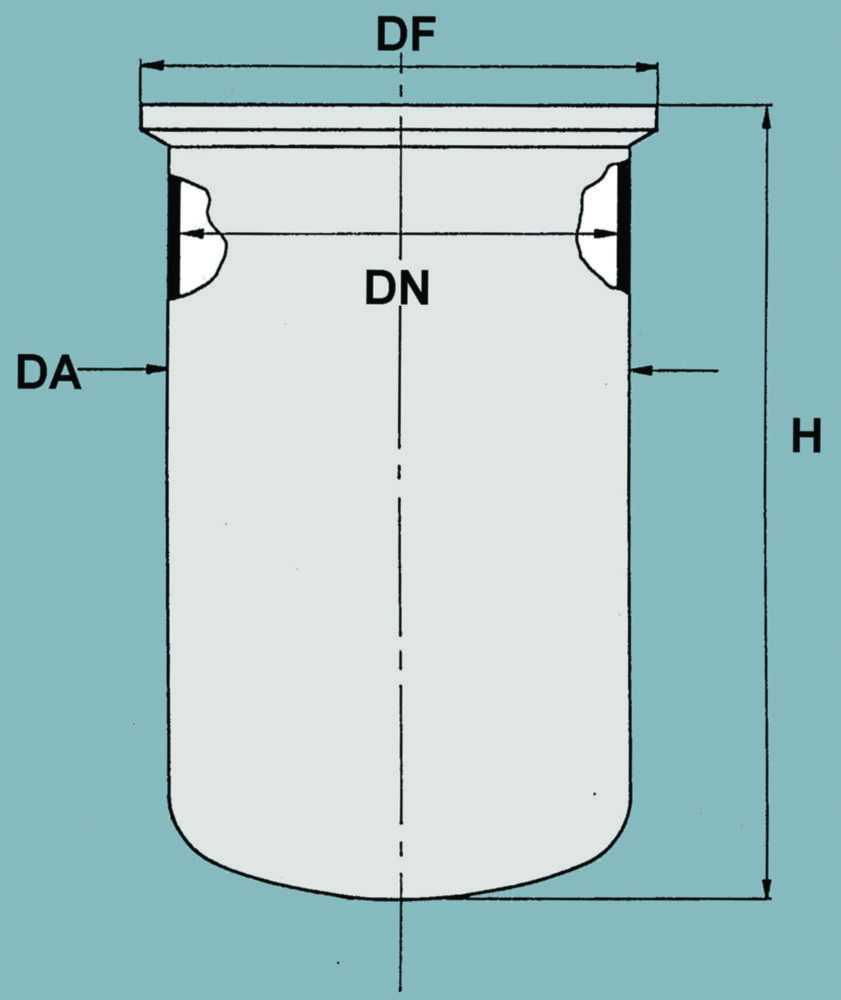

Flat ground flange reaction vessels, unjacketed

Flange in accordance with DIN 12214. Basic flask, without fittings.Form:A = cylindrical formB = short form* with flat bottom** Graduation, blue

Fork clamps for spherical joints

Material: stainless steel. For spherical ground joint connections. With set screw.

Four-neck round-bottom flask, with parallel side necks, DURAN®

Reaction flasks acc. to DIN 12392 and in addition to DIN standard, with 3 parallel side necks, with conical ground joints, with inscription label.

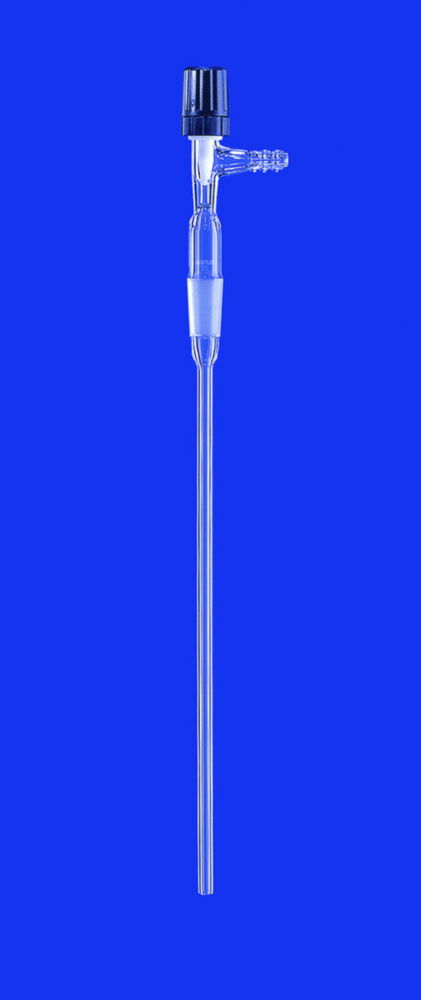

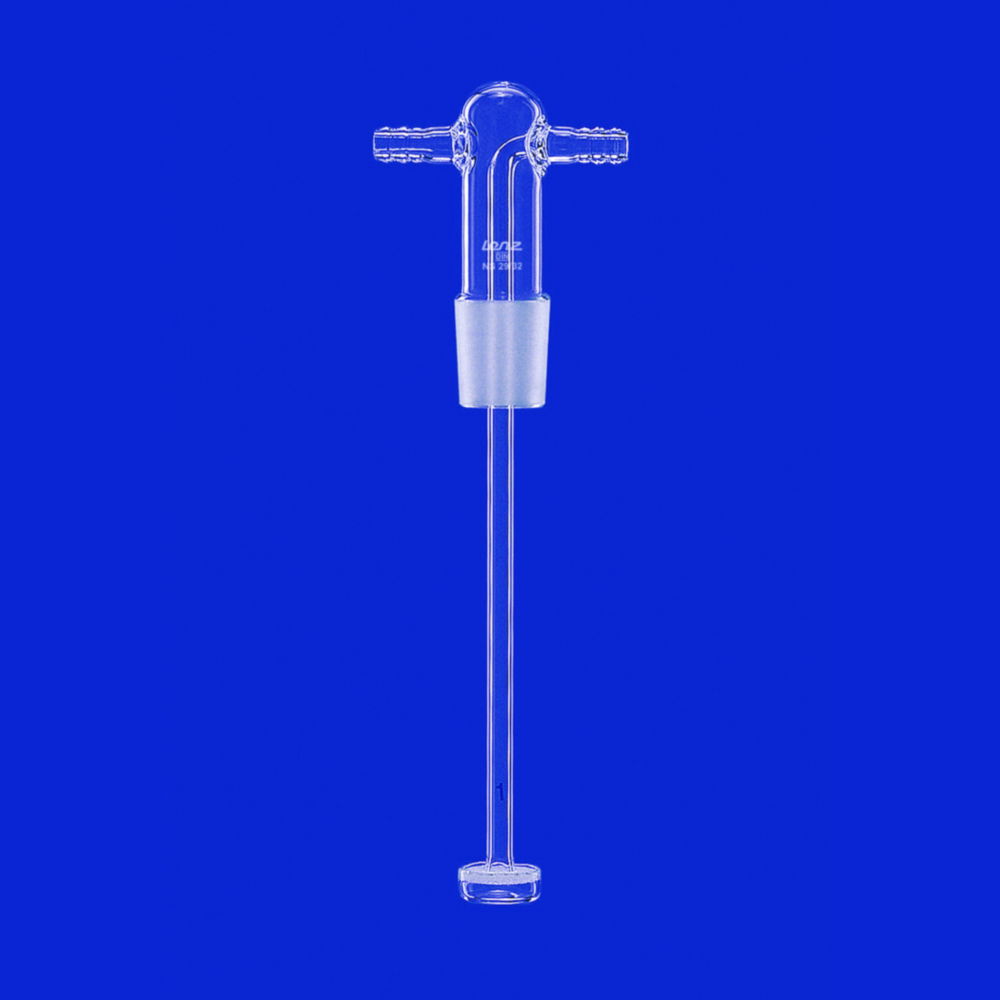

Gas inlet tube with valve stopcock, DURAN® tubing

Made of DURAN® tubing. With valve stopcock for dosing, with glass olive (angle: 90°).

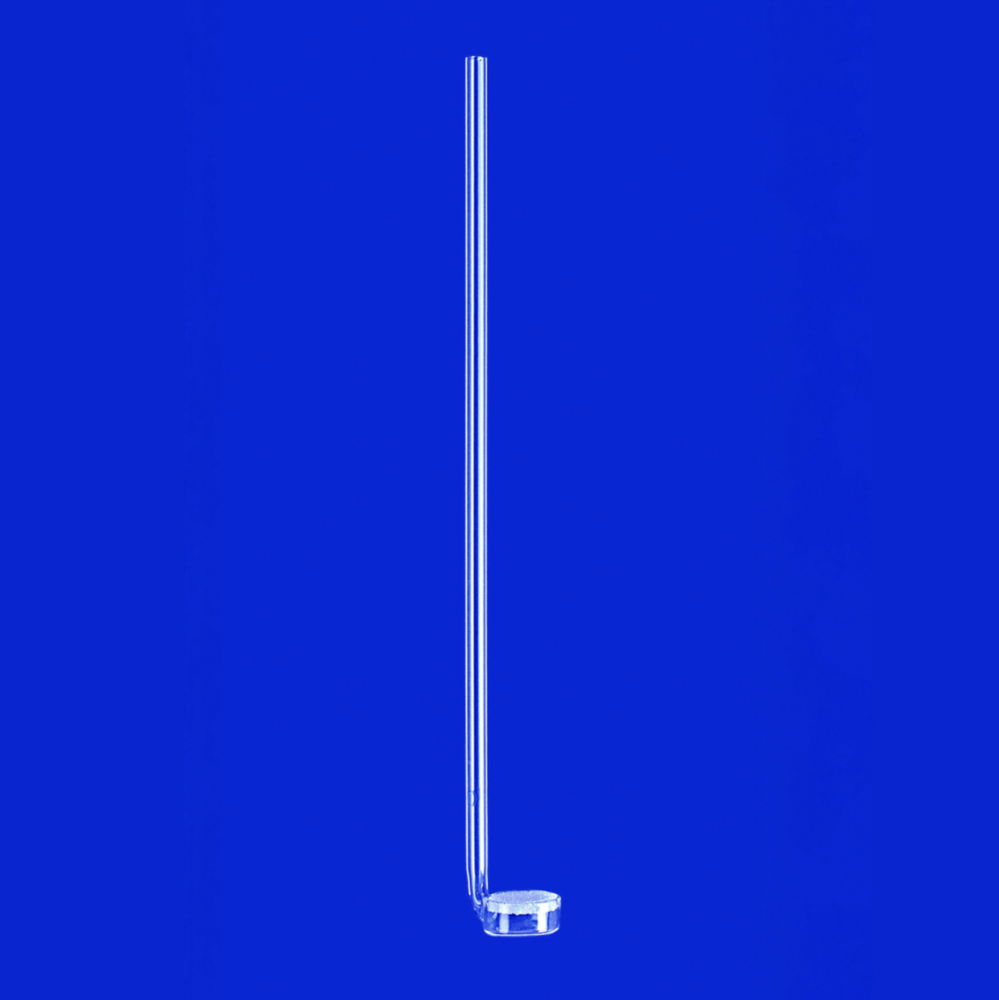

Gas inlet tubes, bent, DURAN® tubing

Made of DURAN® tubing. Bent air leak tubes (angle: 90°), built-in length: 250mm, with NS cone and thin capillary (easily to draw by burner).

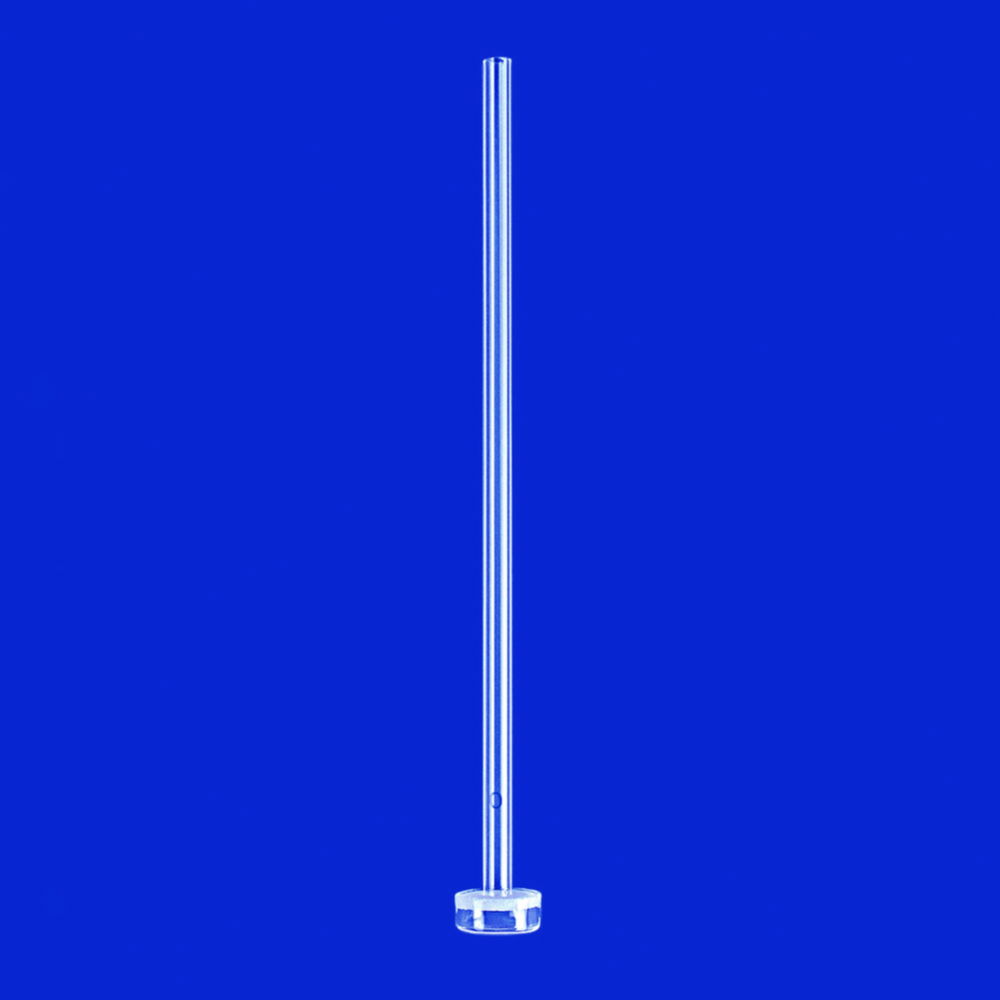

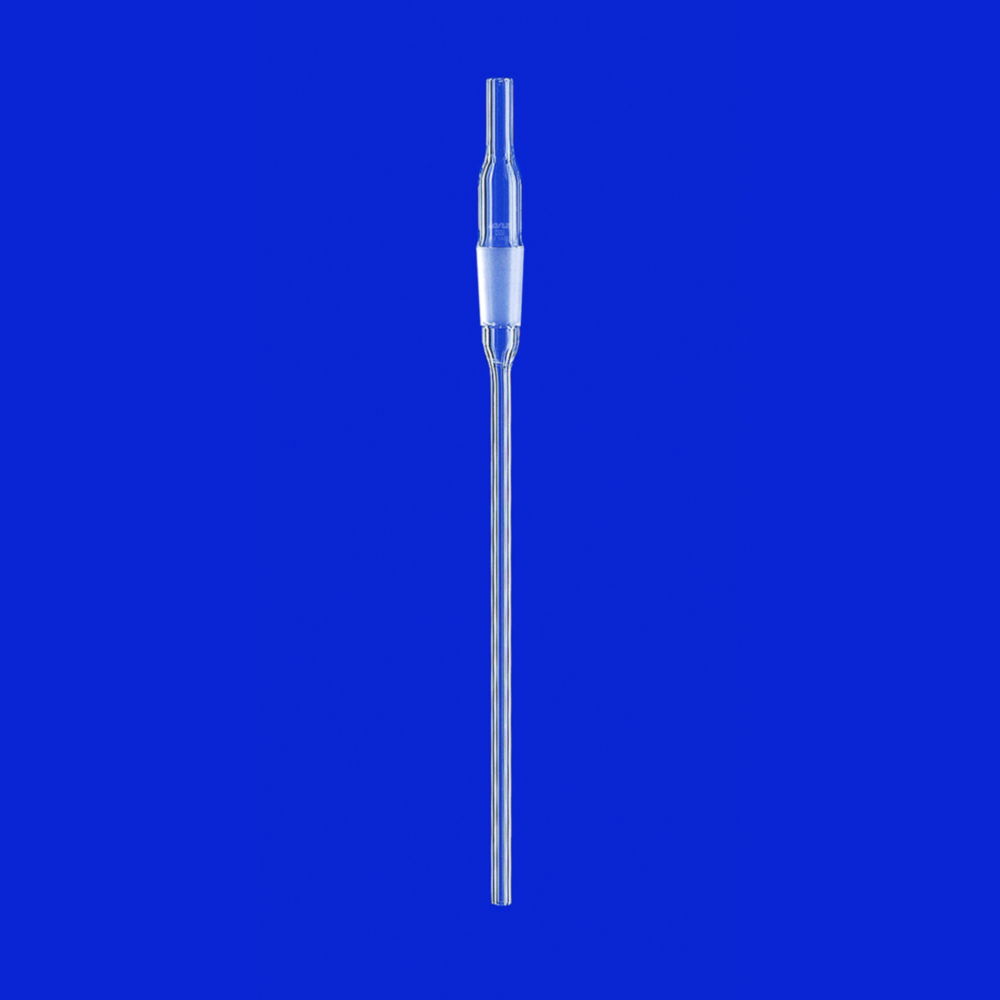

Gas inlet tubes, straight, ground glass joint, DURAN® tubing

Made of DURAN® tubing. Straight air leak tubes, built-in length: 200mm, with NS cone and thin capillary (easily to draw by burner).

Gas wash bottle reservoirs, borosilicate glass 3.3

In accordance with Drechsel.

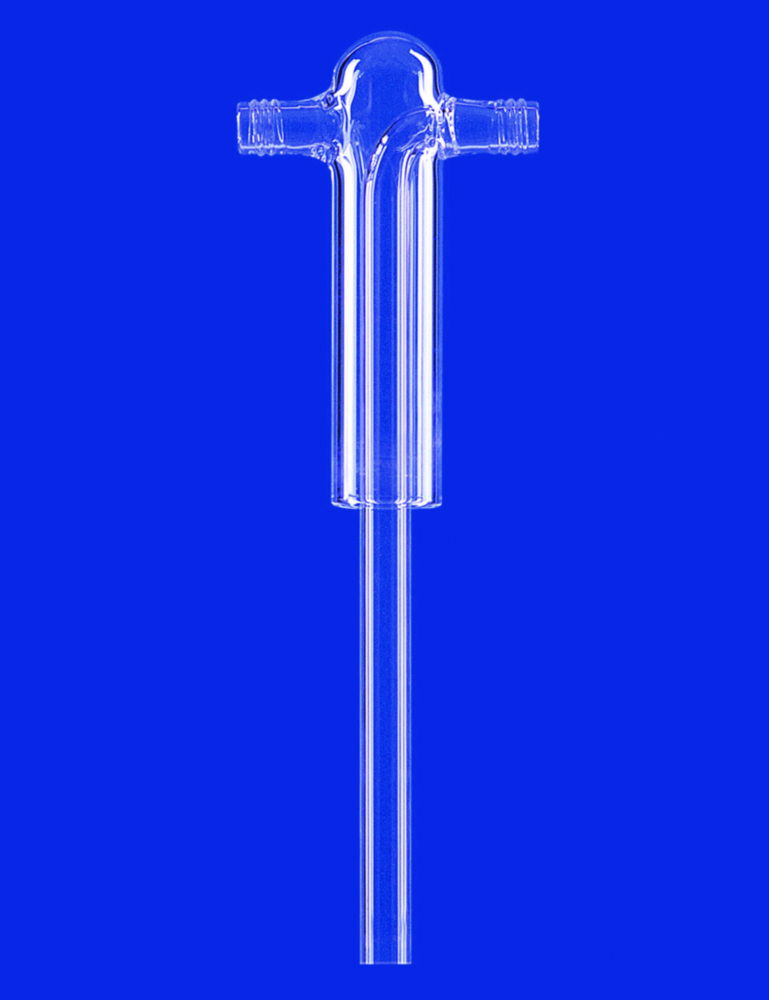

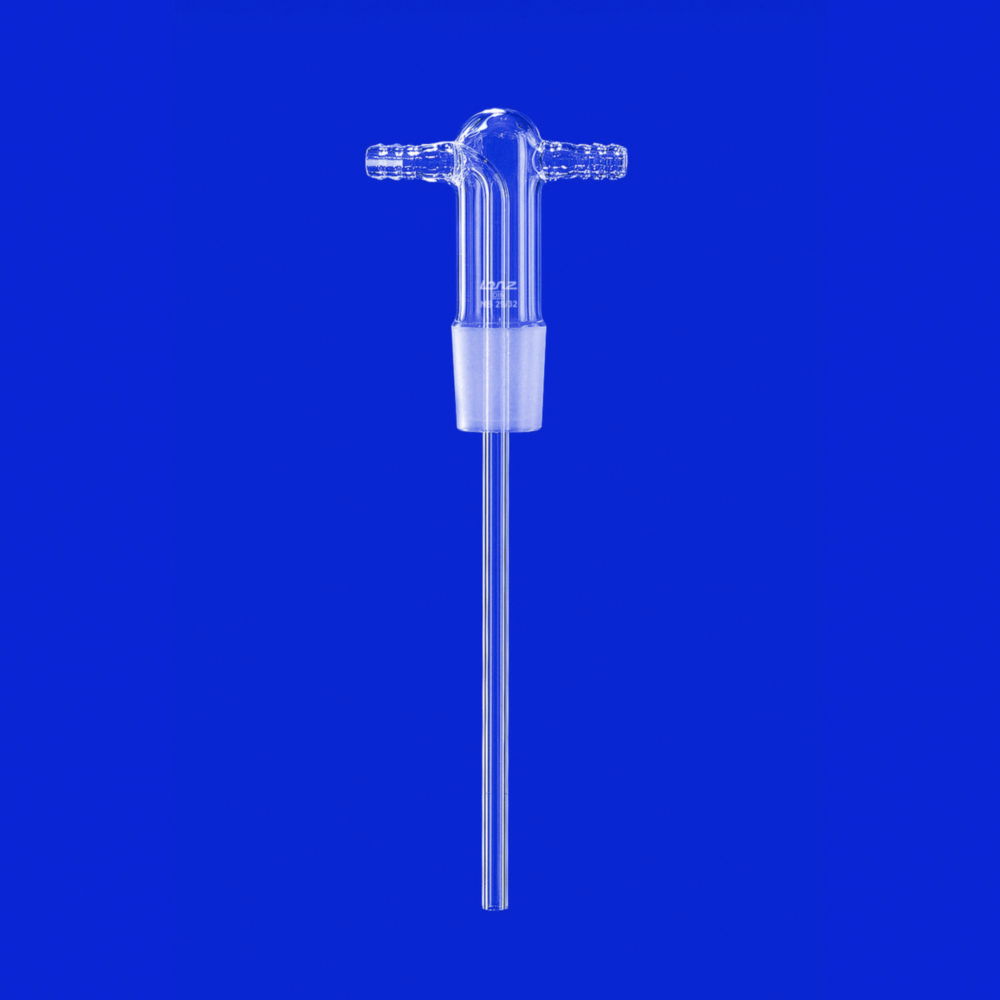

Gas washing bottle heads, DURAN® tubing

Acc. to DIN 12596. DURAN® tubing. Cone NS 29/32.

Gas washing bottle heads, DURAN® tubing, with filter disc

Acc. to DIN 12596. DURAN® tubing. Cone NS 29/32.

Gas washing bottle reservoirs, Drechsel, borosilicate glass 3.3

In accordance with Drechsel. Ground joint 29/32. DIN 12463. Flask height 200 mm, working height 250 mm.

Gas washing bottle, PP

Graduated 250ml polypropylene cylinder with a stable extended base for use in precipitating elements from gas.Gas is dispersed through a removable fitting that has a coarse grade porosity, polyethylene dispersion discSilicone stopper holds 6.3mm O.D. tubes for entrance and exit of gas0.5 psi maximum pressure