Diaphragm vacuum pumps, chemistry design, MD 4C NT

€0.00

Product information "Diaphragm vacuum pumps, chemistry design, MD 4C NT"

- Improved performance, increased pumping speed and lower ultimate vacuum extends applications in both the laboratory and in industrial applications

- Long-life diaphragm with PTFE sandwich construction and unstressed diaphragm support

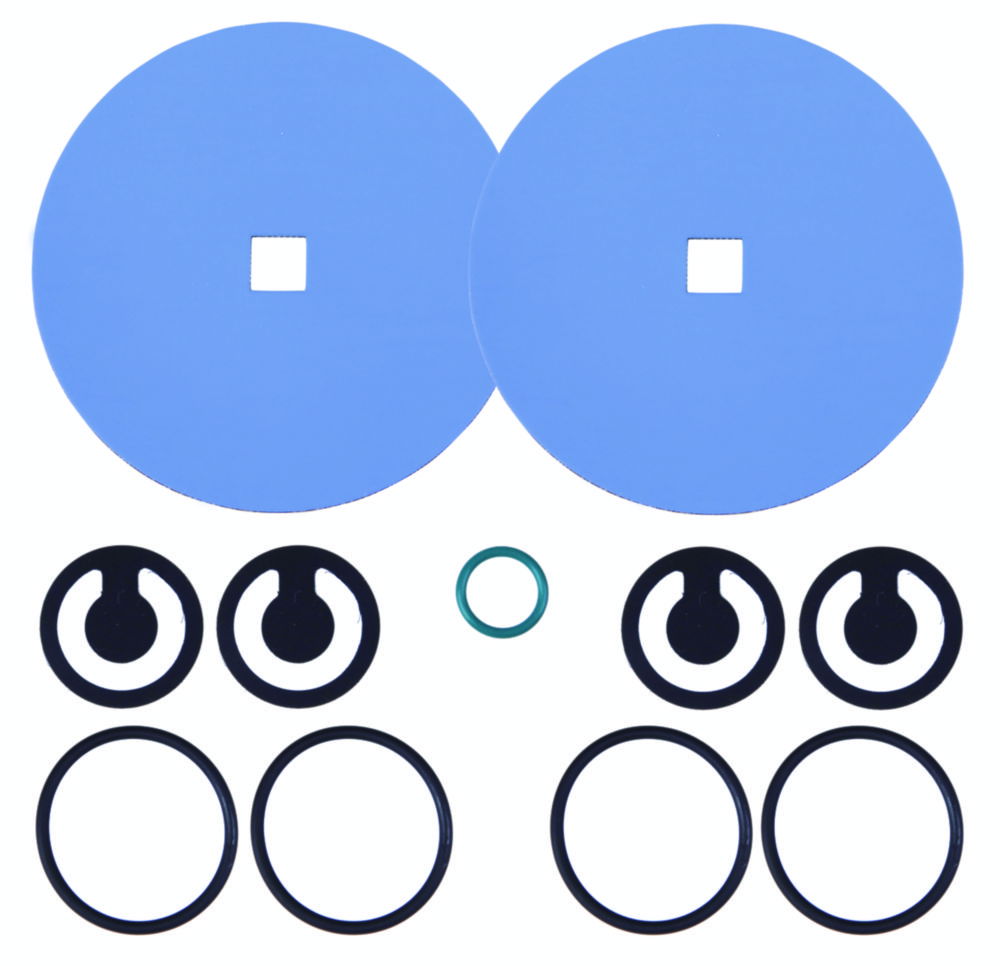

- Easy service/exchange of diaphragm or valves due to novel integrated valve head assembly

- Easy dismantling, cleaning and reassembly without requiring readjustment

- Very quiet and ultra low vibration due to compact drive with patented motor control system. Ideal as a built-in component for sensitive equipment in both the laboratory and in industry

- Easy to clean due to smooth exterior surfaces

- Superior vapour tolerance due to integral tubing connections and gas ballast valve for continuous purge

| Depth: | 328 mm |

|---|---|

| Dimensions (WxDxH): | 243 x 328 x 198 mm |

| Flow rate: | 3.4 m³/h |

| Height: | 198 mm |

| Manufacturer Article Number: | 20736402 |

| No. of stages: | 3 |

| Plug type: | UK |

| Type: | MD 4C NT |

| UNSPSC: | 40151502 |

| Ultimate vacuum: | 1.5 mbar |

| Ultimate vacuum with gas ballast: | 3 mbar |

| Width: | 243 mm |

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Accessories

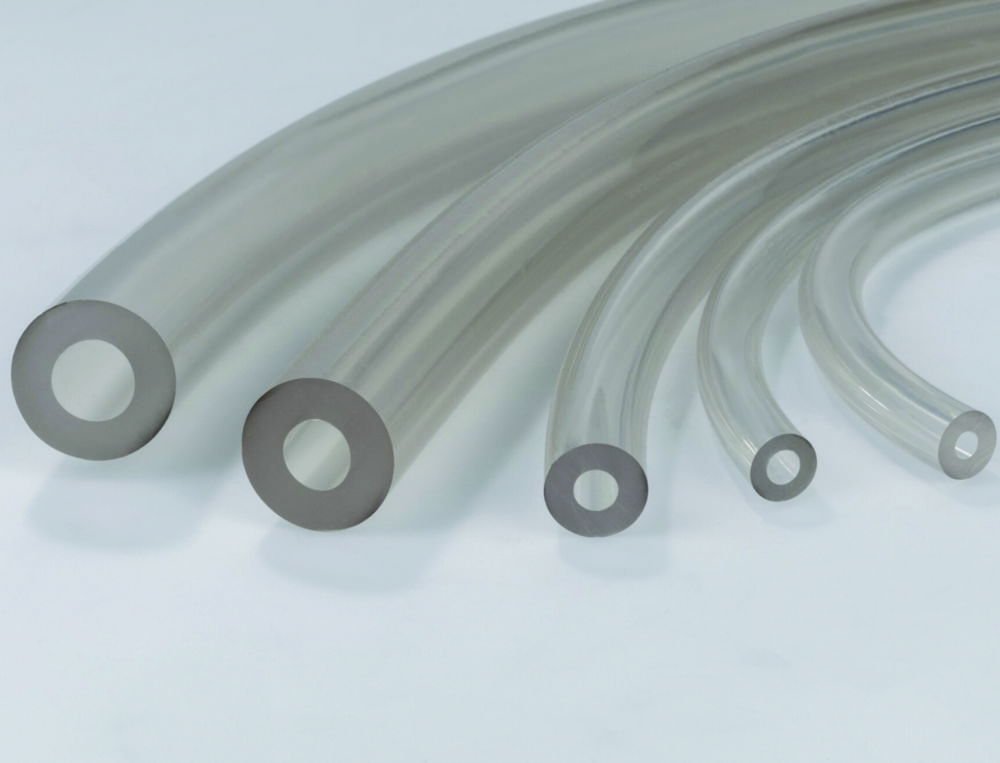

Transparent vacuum tubing for demanding laboratory applications. With its reinforced construction, the hose offers maximum operational safety for vacuum applications. The smooth inner wall prevents deposits and simplifies cleaning processes. The vacuum tubing is also characterised by its excellent chemical resistance and long service life thanks to its high abrasion and bending resistance. Sold per metre.

Other customers also bought

The VARIO® design provides vacuum control by precise and continuous adaption of the chemistry diaphragm pumps motor speed, and includes the vacuum pump, as well as the VACUU·SELECT controller.Improved performance, increased pumping speed and lower ultimate vacuum extends applications in both the laboratory and in industrial applicationsLong-life diaphragm with PTFE sandwich construction and unstressed diaphragm supportEasy service/exchange of diaphragm or valves due to novel integrated valve head assembly. Easy dismantling, cleaning and reassembly without requiring readjustmentVery quiet and ultra low vibration due to compact drive with patented motor control system. Ideal as a built-in component for sensitive equipment in both the laboratory and in industrySuperior vapour tolerance due to integral tubing connections and gas ballast valve for continuous purge Easy to clean due to smooth exterior surfacesThe VARIO® design provides vacuum control by precise and continuous adaption of the chemistry diaphragm pumps motor speed, and includes the vacuum pump, as well as the VACUU·SELECT controller.Improved performance, increased pumping speed and lower ultimate vacuum extends applications in both the laboratory and in industrial applicationsLong-life diaphragm with PTFE sandwich construction and unstressed diaphragm supportEasy service/exchange of diaphragm or valves due to novel integrated valve head assembly. Easy dismantling, cleaning and reassembly without requiring readjustmentVery quiet and ultra low vibration due to compact drive with patented motor control system. Ideal as a built-in component for sensitive equipment in both the laboratory and in industrySuperior vapour tolerance due to integral tubing connections and gas ballast valve for continuous purge Easy to clean due to smooth exterior surfaces

This chemistry vacuum system has a wide range of applications like evacuation, evaporation and pumping of gases and vapors. The separator at the inlet (AK), made of glass with a protective coating, retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) enables near 100 percent solvent recovery.Good chemical resistance and vapor toleranceHigh performance even at low vacuumGood vacuum even with gas ballastQuiet and ultra low vibrationOilfreeSimultaneous operation of two independent vacuum applications, with reliable check valves to prevent interference between systems

This chemistry vacuum system has a wide range of applications like evacuation, evaporation and pumping of gases and vapors. The separator at the inlet (AK), made of glass with a protective coating, retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) enables near 100 percent solvent recovery.Good chemical resistance and vapor toleranceHigh performance even at low vacuumGood vacuum even with gas ballastQuiet and ultra low vibrationOilfreeThis chemistry vacuum system has a wide range of applications like evacuation, evaporation and pumping of gases and vapors. The separator at the inlet (AK), made of glass with a protective coating, retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) enables near 100 percent solvent recovery.Good chemical resistance and vapor toleranceHigh performance even at low vacuumGood vacuum even with gas ballastQuiet and ultra low vibrationOilfree

The diaphragm pumps ME 1C offer a compact and high performance solution. With their easy-to-use functionality, they are the perfect partner for both single and multiple filtrations.One-stage diaphragm pumps are an excellent solution for continuous, oil-free pumping of gases and vapors for modest vacuum requirements. In contrast to water-jet pumps, they do not consume water and therefore do not produce any contaminated waste water in daily use.Vacuum filtration is frequently used for sample preparation in chemistry, microbiology, waste water control and analysis.In the chemistry diaphragm pumps ("C") all major parts in contact with pumped media are made of chemically resistant fluoroplastics. The ME 1C is also often used for solid phase extraction (SPE).An optional manual regulator valve with dial gauge enables variable fine adjustment of the pumping speed and the ultimate vacuum.Gas ballast for reliable pump performance.Two up to four stage chemistry diaphragm pumps (letters in the product name Z, D or V) are equipped with a manual gas ballast valve as standard. The supply of gas ballast minimizes the risk of condensation inside the pump.The diaphragm pumps ME 1C offer a compact and high performance solution. With their easy-to-use functionality, they are the perfect partner for both single and multiple filtrations.One-stage diaphragm pumps are an excellent solution for continuous, oil-free pumping of gases and vapors for modest vacuum requirements. In contrast to water-jet pumps, they do not consume water and therefore do not produce any contaminated waste water in daily use.Vacuum filtration is frequently used for sample preparation in chemistry, microbiology, waste water control and analysis.In the chemistry diaphragm pumps ("C") all major parts in contact with pumped media are made of chemically resistant fluoroplastics. The ME 1C is also often used for solid phase extraction (SPE).An optional manual regulator valve with dial gauge enables variable fine adjustment of the pumping speed and the ultimate vacuum.Gas ballast for reliable pump performance.Two up to four stage chemistry diaphragm pumps (letters in the product name Z, D or V) are equipped with a manual gas ballast valve as standard. The supply of gas ballast minimizes the risk of condensation inside the pump.Diaphragm pumps ATEX-models available on request. Country-specific power cord versions available on request.

Improved performance, increased pumping speed and lower ultimate vacuum extends applications in both the laboratory and in industrial applicationsLong-life diaphragm with PTFE sandwich construction and unstressed diaphragm supportEasy service/exchange of diaphragm or valves due to novel integrated valve head assemblyEasy dismantling, cleaning and reassembly without requiring readjustmentVery quiet and ultra low vibration due to compact drive with patented motor control system. Ideal as a built-in component for sensitive equipment in both the laboratory and in industryEasy to clean due to smooth exterior surfacesWith reduced leakage rate (0.001 mbar x l/s)